معلومات عنا

حول Truer

نحن نقدم معدات وخدمات تصنيع مسحوق معدني كروي عالي الجودة.

Shanghai Truer Technology Co., Ltd. (Truer Technology) is one of the subsidiaries of Truer group, which is mainly responsible for the export business. At present, the main products cover the raw materials, equipment, inspection devices and service for additive manufacturing (AM), Metal Injection Molding (MIM), Powder Metallurgy (PM), automation and other manufacturing fields.

At present, we have 12 factories and more than 30 strategic partners in China for different applications.

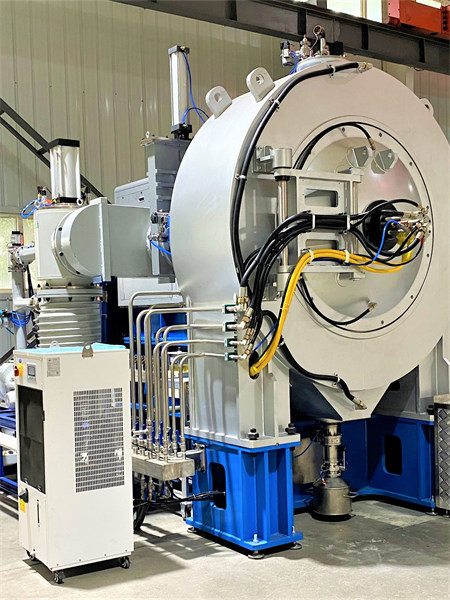

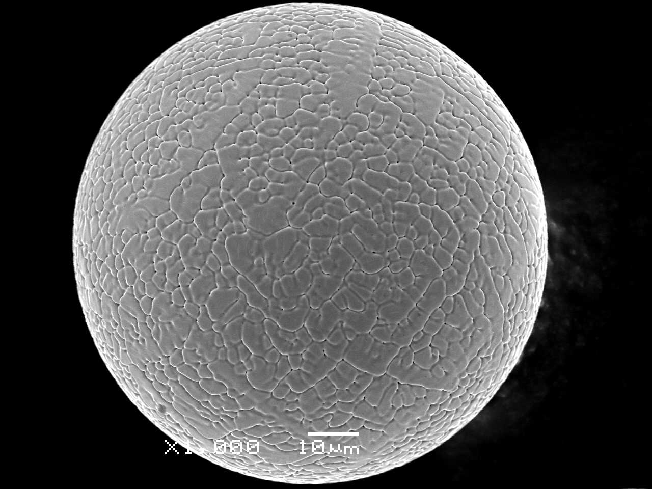

We take the leading in providing innovative desktop level plasma rotating electrode atomizing powder making equipment (SLPA-D30) globally. The maximum rotation speed of consumable electrode rods can reach 50,000 rpm, which is very suitable for the preparation of small batch, multi variety and high-quality metal powders. Using this equipment, we and our customers have successfully developed more than 60 different compositions of high-quality spherical metal powders such as TiNi, Tita, TiAl, TiNbZr and CoCrMo, etc.

In addition, we also provide the medium-sized PREP atomizing equipment/systems (SLPA-N50) and large-scale PREP atomizing equipment/systems (SLPA-N75), which are suitable for industrial production and can provide high-quality metal powders with reasonable cost for 3D printing and other applications.

We are committed to providing the suitable plasma rotating electrode atomizing metal powder making equipment or high-quality PREPed metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc. We will continue to invest in R&D to optimize our plasma rotating electrode atomizing metal powder making equipment and production process parameters, in order to provide customers with the best quality and high-end PREP atomizing equipment and metal powders.

قيادة الطريق في الابتكار

نسعى جاهدين لبناء العلامة التجارية الدولية في هذا الصناعة

بالاعتماد على منصة المختبر الرئيسي للدولة للمواد المعدنية المسامية ، أنشأت الشركة مركز الابتكار المشترك للطباعة ثلاثية الأبعاد المعدنية ، واضطلعت بأكثر من 30 مشروعًا وطنيًا ومحليًا في مجال العلوم والتكنولوجيا ، مثل مشروع المؤسسة القوية الصناعية للوزارة الصناعة وتكنولوجيا المعلومات ، وصندوق ابتكار الشركات الصغيرة والمتوسطة التابع لوزارة العلوم والتكنولوجيا ، والمشروع الوطني للبحث والتطوير. تقدمت بطلب للحصول على أكثر من 60 براءة اختراع (تم ترخيص 26 عنصرًا) في مشروع قاعدة صناعية قوية لوزارة الصناعة ثلاثية الأبعاد ، وقادت صياغة 5 معايير وطنية وصناعية ، وشاركت في صياغة 8 معايير ، والشركة هي المجلس عضو في تحالف صناعة المواد المضافة الصينية ، وعضو اللجنة الفنية الوطنية لتوحيد معايير التصنيع الإضافي ، وعضو فرع التصنيع الإضافي لجمعية الهندسة الميكانيكية الصينية ، وفي عام 2017 تم إدراجه في قائمة أفضل 100 استثمار صناعي مضاف في الصين.

مصنع قوي في الصين

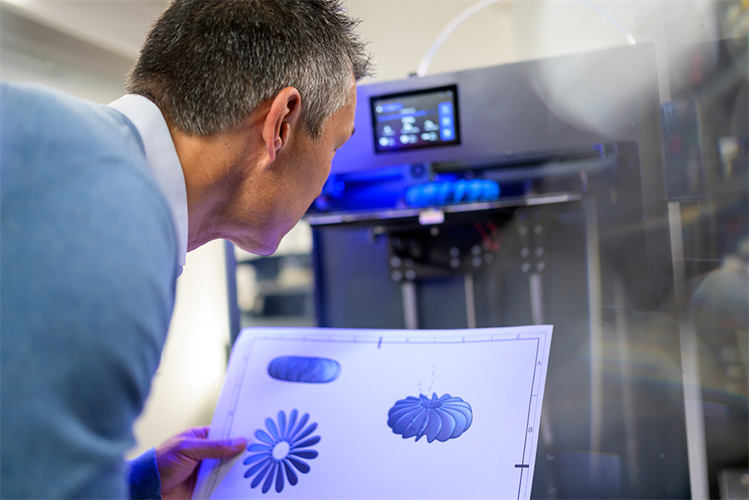

Our factory was established in Xi‘an in 2013, we are specializing in the development and production of plasma rotating electrode atomizing powder making (PREP) technology and equipment, metal powders, powder bed selective electron beam melting 3D printing (SEBM) technology and equipment.

خط إنتاج النزاهة

High quality and high productivity are not possible without lean production lines. Our factories use advanced equipment and modern management to ensure that our production efficiency and quality meet demands. Not only that, we are actively researching and developing more efficient production lines.

تجربة صناعة غنية

We are the leading enterprise in China in Additive Manufacturing with more than 10 years experiences of R&D and production in 3D printing technology & equipment (PBF-SEBM) and metal powder making technology & equipment (PREP).

Research & Innovation

We constantly strive to develop new processes and devices to improve the efficiency. We try our best to be suitable for industrial production and provide high quality metal powders with high-cost performance for 3D printing and other applications.

مورد مرن

We are committed to recommending the best suitable plasma rotating electrode atomizing equipment or high quality PREPed metal powders to meet different customers’ requirements.