By Shanghai Truer

Background

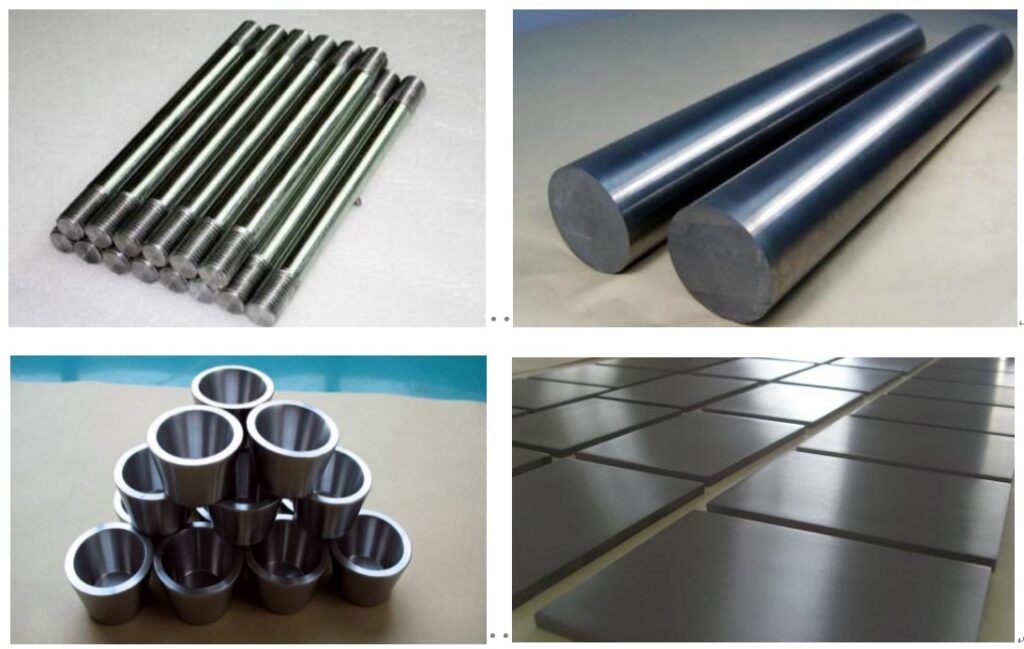

Molybdenum has excellent properties such as high temperature strength, good electrical and thermal conductivity, good heat and fatigue resistance, and low toxicity. It is used in aerospace, nuclear industry, electronics industry, and medical fields. However, its high melting point, difficult forming, and poor processing performance significantly affect its wider application.

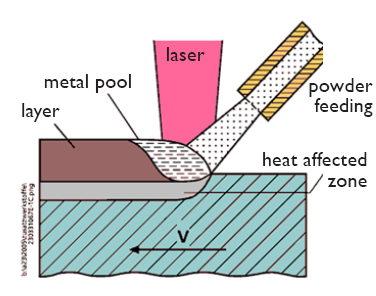

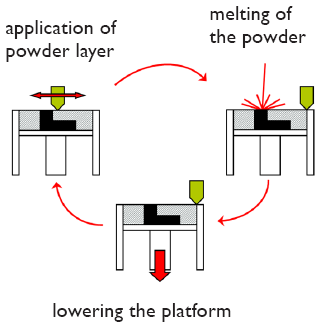

With the advancement of technology, additive manufacturing processes have emerged, providing a new means for the deep processing of molybdenum.

Potential additive manufacturing processes include: Laser Engineered Net Shaping(LENS), Direct Energy Deposition(DED), Powder Bed Selective Melting (PBF-SLM, PBF-SEBM), etc. These process methods use metal molybdenum or molybdenum alloy powder as raw materials and manufacture parts using different energy sources.

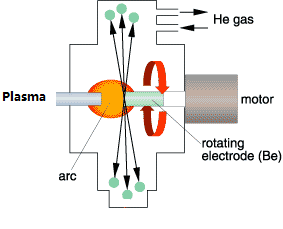

In order to obtain high-quality, spherical molybdenum powder or molybdenum alloy powder that meets production requirements, plasma rotating electrode atomization process is a good choice.

Experiments

Produce a batch of molybdenum powder using our company’s PREP equipment for performance analysis.

Table 1 Main Process Parameters

| Current(A) | Rotating speed (rpm) | Feeding speed(mm/min) |

| 2400-2700 | 12000-17000 | 0.8-1.0 |

Results and Analysis

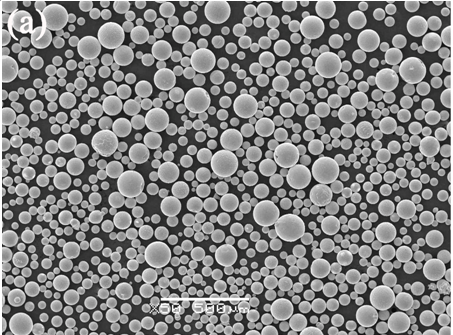

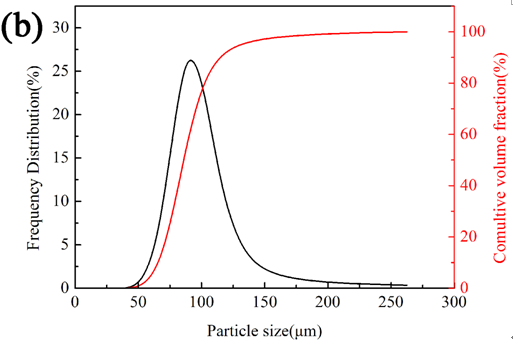

The particle size of the molybdenum powder produced conforms to the unimodal normal distribution characteristics, with D50=85μm. The powder particle size is mainly distributed between 60-100μm (more than 80%).

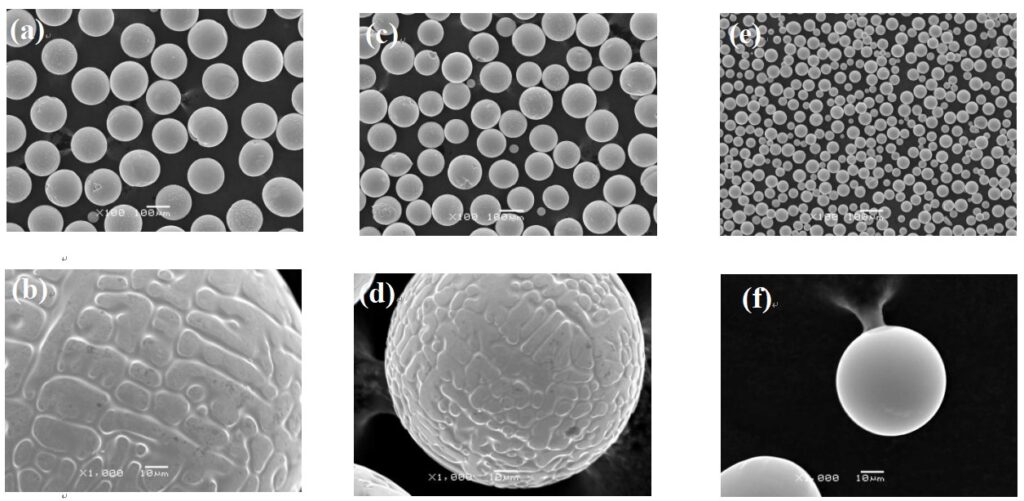

The particle morphology was observed under SEM, and the results are as follows.

Fig. 2: Surface microstructure of Mo powders with different particle sizes prepared by PREP method:

a, b) ≥ 150 μm (large particles), with “more dendrites+fewer cell crystals”;

(c, d) 45-150 μm (medium particles), with fewer dendrites and more cellular crystals;

(e, f) ≤ 45 μm (small particles), smooth surface without obvious crystalline structure

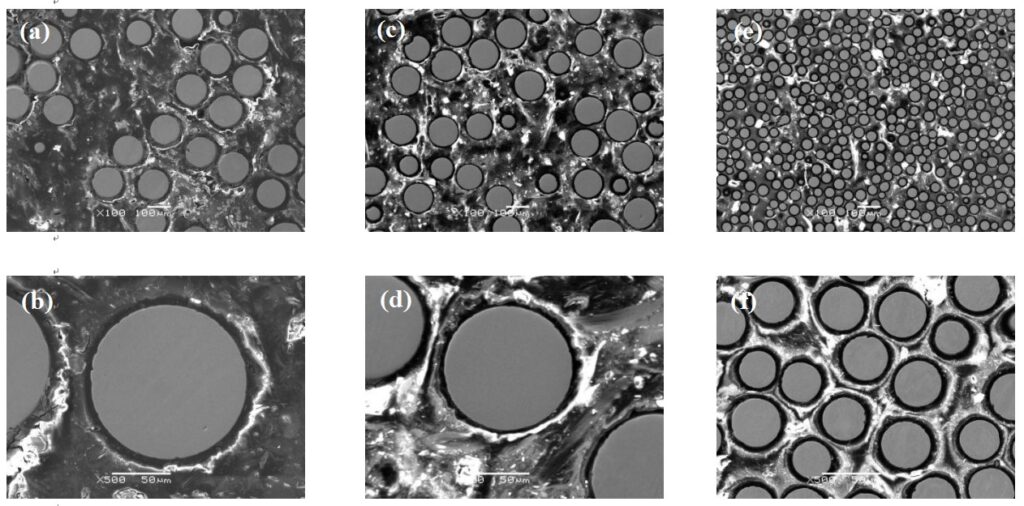

Fig. 3: Cross sectional morphology of Mo powders with different particle sizes prepared by PREP method: a, b) ≥ 125 μm; (c,d) 45-125μm; (e,f) ≤45μm

As shown in Fig. 3, the cross-section of the powder particles is smooth and dense, with no hollow spheres found and no internal pores present.

Table 2 Physical Properties of Mo Powder Prepared by PREP Method

| Particle size/(μm) | Flowability/(s/50g) | Apparent density/(g/cm3) | Tap density/(g/cm3) | angle of repose/(°) |

| 45~250 | 10.2 | 6.07 | 6.4 | 25.0 |

| 60~125 | 11.2 | 5.94 | 6.2 | 26.5 |

Fig. 4 Nitrogen/oxygen gap element content of Mo powders with different particle sizes prepared by PREP method

As shown in Fig.4,

The nitrogen impurity content is very low throughout the entire particle size range;

As the powder particle sizes decrease, the oxygen content increases, but not exceeding 0.01%.

Conclusions

- By using plasma rotating electrode atomization technology, molybdenum powder is mainly composed of regular spherical particles with high sphericity and particle size distribution mainly ranging from 60 to 100 μm.

- The powder with particle size ≥ 150 m and 45-150 μm has a mixed microstructure of dendrites and cell crystals, while the powder particles with particle size ≤ 45 μm have a smooth surface without obvious crystalline structure. The powder is basically a solid ball.

- Within a certain range, molybdenum powder with a wide particle size distribution has better flowability and higher bulk density. The increment of interstitial elements in the powder is relatively low, and as the powder particle sizes decrease, the oxygen content increases, but not exceeding 0.01%.

- The prepared molybdenum powder meets the requirements of 3D printing technology for powder material properties.