CONDUZIDO POR ESPECIALISTAS APAIXONADOS

A liderança da manufatura aditiva

We have been maximizing the levels of the critical manufacturing environment, and we have successfully developed PREP atomizing system, SEBM 3D printing system and more than 60 grades of high-quality spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, and CoCrMo, etc.

Anos de fabricação

Experiência

Qualidade e inovação contínuas

Contamos com a plataforma de inovação do State Key Laboratory of Porous Metal Materials para estabelecer um centro de inovação conjunto para Metal Additive Manufacturing desde 2010, e realizar as inovações científicas e tecnológicas de Additive Manufacturing em conjunto com instituições de pesquisa científica de alto nível e bem conhecidas especialistas em casa e no exterior.

We start the commercial production of PREP atomizing system and SEBM printing system since 2013 with high quality requirements.

SOBRE Truer

We are Professional In Additive Manufacturing

We specializes in R&D, Production, Sales and Technical Service of Plasma Rotating Electrode atomization equipment (PREP) & high-quality spherical PREPed metal powders, and Powder Bed Selective Electron Beam Melting 3D printing equipment (SEBM) & SEBMed components.

Linha de produção enxuta

Temos uma linha de produção moderna, equipamentos de alta eficiência e especialistas qualificados, que podem atender às necessidades dos clientes em todo o mundo.

Pesquisa e inovação

Temos uma equipe independente, enérgica, cooperativa e inovadora para pesquisa e desenvolvimento contínuos. Fazemos o investimento anual em pesquisa, desenvolvimento e inovações.

- Developed a new generation of PREP atomizing equipment for the demands of Additivie Manufacturing, HIP, High-end Powder Metallurgy, Surface Technology, etc.

- Taking the leading in realizing vertical PREP atomizing systems in the world.

- Developed more than 60 kinds of high-quality spherical metal powder.

- The first to launch the commercial SEBM 3D printing systems (PBF) in China.

- Developed hundreds of lightweight, complex, high-performace metal components with our SEBM system.

- Provided more than 10,000 pieces of customized orthopedic implant materials to more than 20 authoritative hospitals in China

SLPA-N50

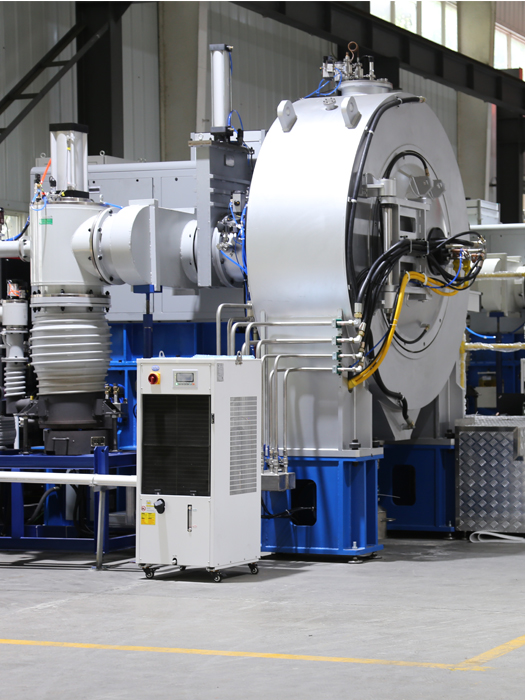

The medium-scale PREP system (SLPA-N50,Medium-sized) is purposely designed for continuous, industrial mass production of high-quality spherical metal powders.

Grupos-alvo:

Os usuários que fazem a produção industrial contínua de pós metálicos esféricos de alta qualidade.

SLPA-D30

O sistema PREP de pequena escala (SLPA-D, nível de desktop) foi projetado propositadamente para P&D de novos pós de liga e produção de pequenos lotes de pós de alta qualidade.

Grupos-alvo:

Pesquisa científica, experimento, desenvolvimento e produção de pó metálico esférico de alta qualidade em universidades e institutos de pesquisa (especialmente adequado para os novos materiais).

SLPA-N75

The large-scale PREP equipment (SLPA-N75) is purposely designed for continuous, industrial mass production of high quality spherical Titanium alloy powders.

Target groups:

High-quality and large-scale industrial production of spherical Ti-alloys powder users, and the powders can be used for mass production of parts in the fields of additive manufacturing, high-end powder metallurgy, laser cladding, etc.

Princípio do Processo de Eletrodo Rotativo de Plasma (PREP)

A tocha de plasma de alta temperatura derrete uma face final da haste do eletrodo rotativo de alta velocidade, então o filme líquido de metal fundido voa para fora e se quebra em gotas sob a ação da força centrífuga gerada pela rotação de alta velocidade. Algumas gotículas colidirão com moléculas de gás inerte e se quebrarão em gotículas menores. Todas essas gotículas são gradativamente solidificadas sob a ação da tensão superficial durante o voo e tornam-se esféricas, e finalmente atingem a parede da câmara de atomização e são resfriadas em pós metálicos esféricos.

Por que mais verdadeiro

Vamos confiar na Truer e trabalhar com a Truer

We are committed to providing the suitable plasma rotating electrode atomization metal powder making equipment/system or high-quality PREP metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc.

We will continue to invest in R&D to optimize our PREP atomizing system together with production process parameters, to provide customers with the best quality, high-end metal powders to support customers to achieve the required high-performance components finally.

Qualidade é a mais alta prioridade

We continuously monitor each stage of the manufacturing processes and conduct the required testing before delivery to ensure that the products can meet customers' requirements.

Certificação completa da indústria

We hold more than 100 patents in 3D printing areas and have led the development of national and industry standards many times.

NOSSAS ESPECIALIDADES

Descubra o que nos torna grandes

We have developed the new generation PREP atomizing systems targeted at the demands of metal powders for Additive Manufacturing, Hot Isostatic Process, High-end Powder Metallurgy, Surface Technology, etc.

And we are developing the world’s first vertical commercial PREP atomizing system.

And we have also developed more than 60 different compositions of high-quality spherical metal powders, some of them are quite new material types.

Ampla experiência

Com mais de 10 anos de experiência na indústria de manufatura aditiva, podemos oferecer vários produtos de toda a cadeia da indústria para satisfazer suas necessidades......

seleção completa

We provide a complete selection of PREP atomizing technology and powder bed SEBM 3D printing technology, including PREP equipment, PREPed Metal Powders, SEBM equipment, SEBMed components.

Desenvolvimento contínuo

We offer continuous development and investment on PREP atomizing technology and powder bed SEBM 3D printing technology. And we are constantly updating our technologies, products and services.

Atendimento ao Cliente

We prioritize the needs of our customers. We are always at your service before, during, and after the sales.

Customização de produto

For PREPed metal powders, we can provide the production of customized metal powders or manufacturing the metal powders with the raw materials provided by customers, whatever small batch or series production with the reasonable cost.

Explore mais

Para saber mais sobre nossos produtos, continue lendo...

Contact Us For Excellent Service & Quality

Looking for a professional additive manufacturing supplier and getting the newest quotations for our PREP atomizing system, or have any other questions, please click the button and leave us messages.

Blog mais recente

The preparation and research of Spherical Molybdenum Powder for 3D Printing prepared by Plasma Rotating Electrode Process

By Shanghai Truer Background Molybdenum has excellent properties such as high temperature strength, good electrical and thermal conductivity, good heat and fatigue resistance, and low toxicity. It is used in aerospace, nuclear industry, electronics industry, and medical fields. However, its

The Application of Molybdenum and its alloys on 3D printing

Adapted from B01, Issue 23, 2023 of World Metal Herald Background As is well known, due to its excellent high-temperature strength, molybdenum metal has become an indispensable raw material in many industries. In practical applications, sometimes complex shaped components are