With the official approval of the National Medical Products Administration (NMPA) on July 20, 2023, the titanium alloy acetabular cup system developed by our first partner using the electron beam 3D printing equipment (Y150) produced by our company has been approved. So far, more than 10 customers in the medical field are using our company’s full industry chain resources such as electron beam 3D printing powder raw materials, equipment (Y150, Y150Plus, T200), and processes to develop orthopedic implant products and register Type 3 of medical devices. This marks the establishment of an independent, controllable, and innovative research and production system for domestically produced electron beam 3D printed orthopedic implants.

The printing materials used include titanium alloy, tantalum metal, zirconium niobium alloy, covering all orthopedic application scenarios such as standardized and personalized hip joints, knee joints, spine, and maxillofacial.

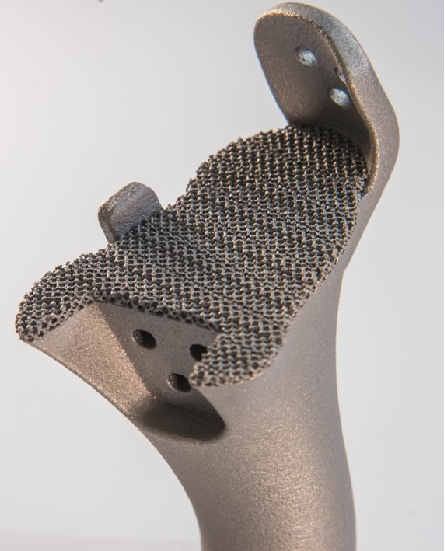

In the process of cooperating with our customers, our company fully leverages the advantages of the entire industry chain of electron beam 3D printing, providing comprehensive one-stop services including raw material support, equipment operation, software support, scanning strategy, and process optimization. We also assist customers in verifying raw materials, equipment, and processes. The dimensional accuracy, mechanical properties, chemical composition, and pore structure characteristics of the samples meet the requirements of relevant national and industry standards.

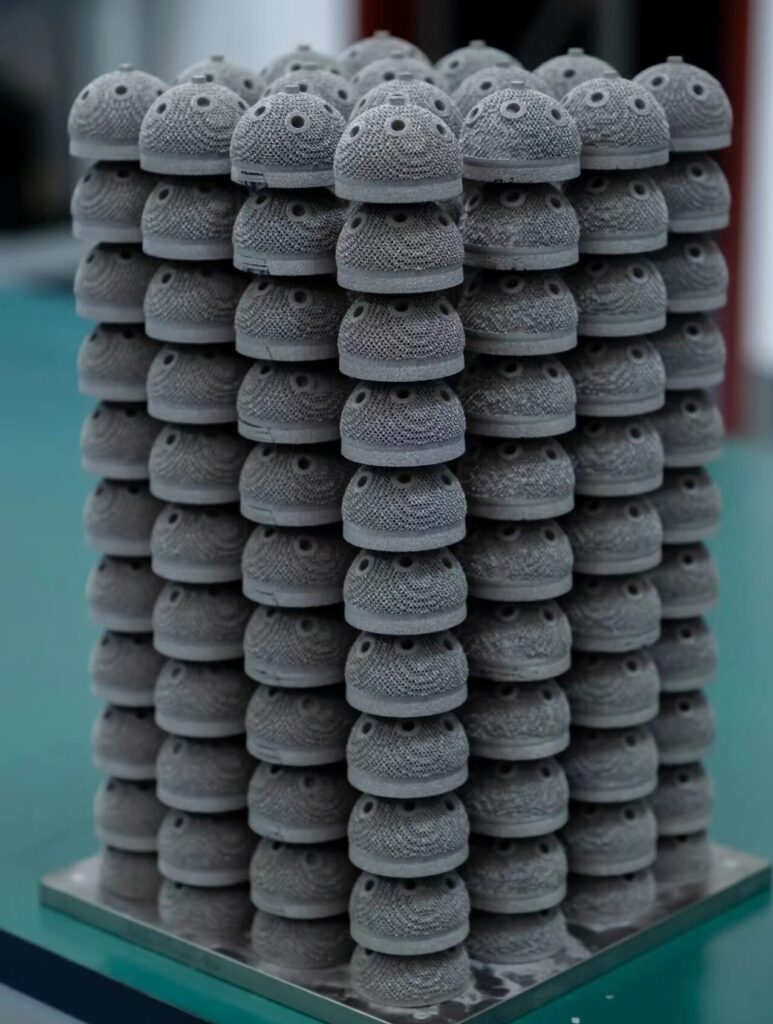

The pore structure of the printed acetabular cup has the characteristics of 100% three-dimensional connectivity, high porosity, high friction coefficient, and low powder residue, which has excellent bone ingrowth effect and ensures the initial stability of the prosthesis after implantation.

Electron beam 3D printing technology has the characteristics of high energy density, fast production efficiency, low forming stress, and pollution-free vacuum environment. It does not require subsequent heat treatment and wire cutting in the manufacturing of orthopedic implants, and can be stacked and printed, making it particularly suitable for low-cost, batch based rapid manufacturing of orthopedic implants.

Due to the high technological threshold of the equipment and the lack of commercial products for core components and software such as electron guns, there are relatively few domestic and foreign enterprises with the ability to manufacture commercial electron beam 3D printing equipment. China’s electron beam 3D printing equipment for orthopedic implants relies on imports, with high equipment prices, high maintenance costs, long product development cycles, and a single material process package.

As the earliest enterprise in China to develop electron beam 3D printing equipment, our company has successively broken through the technical barriers of core components, scanning path planning, processes, and software, and launched the first domestically developed commercial electron beam 3D printing equipment with independent intellectual property rights.

In addition, combined with the company’s independent intellectual property rights of plasma rotating electrode atomization powder equipment (SLPA-D30, SLPA-N50 e SLPA-N75), the preparation of high-quality medical spherical metal powders such as high melting point tantalum and high activity zirconium niobium alloy, as well as the development of electron beam 3D printing technology, have been achieved, and more than 100 clinical trials have been completed.

In 2023, the company took the lead in developing a high-power, high-precision, and long-life low-cost inter thermal electron gun internationally. In response to the manufacturing needs of orthopedic implants, the company launched a series of medical electron beam 3D printing equipment equipped with different power, indirect heating electron guns (as shown in Figure 2). The equipment has reached the international leading level in electron gun power, forming accuracy, cathode life, and cost, and can achieve high-precision, low-cost, and batch rapid manufacturing of various medical metal orthopedic implants.

SEBM – Y150 Plus

SEBM – Y150

SEBM – T200