DIRIGIDOS POR EXPERTOS APASIONADOS

El líder de la fabricación aditiva

We have been maximizing the levels of the critical manufacturing environment, and we have successfully developed PREP atomizing system, SEBM 3D printing system and more than 60 grades of high-quality spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, and CoCrMo, etc.

años de fabricación

Experiencia

Alta calidad e innovación continua

Confiamos en la plataforma de innovación del State Key Laboratory of Porous Metal Materials para establecer un centro de innovación conjunto para la fabricación aditiva de metales desde 2010, y llevamos a cabo las innovaciones científicas y tecnológicas de la fabricación aditiva junto con instituciones de investigación científica de alto nivel y reconocidos expertos en el país y en el extranjero.

We start the commercial production of PREP atomizing system and SEBM printing system since 2013 with high quality requirements.

ACERCA DE

We are Professional In Additive Manufacturing

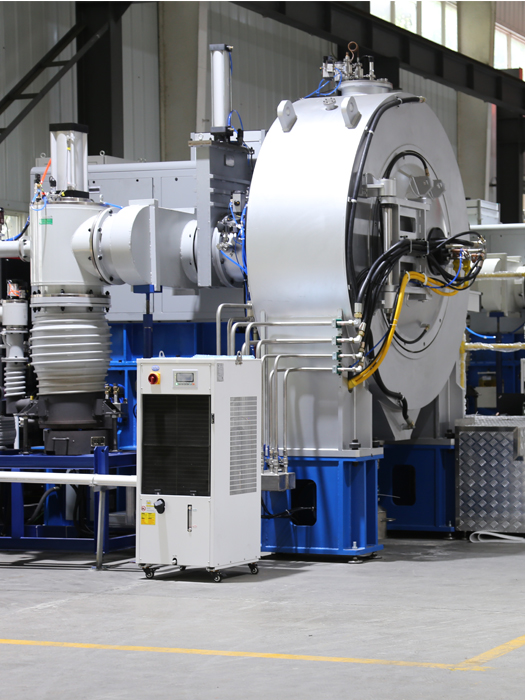

We specializes in R&D, Production, Sales and Technical Service of Plasma Rotating Electrode atomization equipment (PREP) & high-quality spherical PREPed metal powders, and Powder Bed Selective Electron Beam Melting 3D printing equipment (SEBM) & SEBMed components.

Línea de producción ajustada

Contamos con una línea de producción moderna, equipos de alta eficiencia y expertos calificados que pueden satisfacer las necesidades de los clientes en todo el mundo.

Investigación e Innovación

Contamos con un equipo independiente, enérgico, cooperativo e innovador para la investigación y el desarrollo continuos. Hacemos la inversión anual para investigación, desarrollo y nuevas innovaciones.

- Developed a new generation of PREP atomizing equipment for the demands of Additivie Manufacturing, HIP, High-end Powder Metallurgy, Surface Technology, etc.

- Taking the leading in realizing vertical PREP atomizing systems in the world.

- Developed more than 60 kinds of high-quality spherical metal powder.

- The first to launch the commercial SEBM 3D printing systems (PBF) in China.

- Developed hundreds of lightweight, complex, high-performace metal components with our SEBM system.

- Provided more than 10,000 pieces of customized orthopedic implant materials to more than 20 authoritative hospitals in China

SLPA-N50

The medium-scale PREP system (SLPA-N50,Medium-sized) is purposely designed for continuous, industrial mass production of high-quality spherical metal powders.

Grupos destinatarios:

Los usuarios que realizan la producción industrial continua de polvos metálicos esféricos de alta calidad.

SLPA-D30

El sistema PREP a pequeña escala (SLPA-D, nivel de escritorio) está diseñado específicamente para la I+D de nuevos polvos de aleación y la producción de lotes pequeños de polvos de alta calidad.

Grupos destinatarios:

Investigación científica, experimentación, desarrollo y producción de polvo metálico esférico de alta calidad en universidades e institutos de investigación (especialmente adecuado para los nuevos materiales).

SLPA-N75

The large-scale PREP equipment (SLPA-N75) is purposely designed for continuous, industrial mass production of high quality spherical Titanium alloy powders.

Target groups:

High-quality and large-scale industrial production of spherical Ti-alloys powder users, and the powders can be used for mass production of parts in the fields of additive manufacturing, high-end powder metallurgy, laser cladding, etc.

Principio del proceso de electrodo rotatorio de plasma (PREP)

El soplete de plasma de alta temperatura funde un extremo de la varilla del electrodo giratorio de alta velocidad, luego la película líquida de metal fundido sale volando y se rompe en gotas bajo la acción de la fuerza centrífuga generada por la rotación de alta velocidad. Algunas gotas chocarán con moléculas de gas inerte y se romperán en gotas más pequeñas. Todas estas gotas se solidifican gradualmente bajo la acción de la tensión superficial durante el vuelo y se vuelven esféricas, y finalmente alcanzan la pared de la cámara de atomización y se enfrían en polvos metálicos esféricos.

¿Por qué más cierto?

Confiemos en Truer y trabajemos con Truer

We are committed to providing the suitable plasma rotating electrode atomization metal powder making equipment/system or high-quality PREP metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc.

We will continue to invest in R&D to optimize our PREP atomizing system together with production process parameters, to provide customers with the best quality, high-end metal powders to support customers to achieve the required high-performance components finally.

La calidad es la máxima prioridad

We continuously monitor each stage of the manufacturing processes and conduct the required testing before delivery to ensure that the products can meet customers' requirements.

Certificación completa de la industria

We hold more than 100 patents in 3D printing areas and have led the development of national and industry standards many times.

NUESTRAS ESPECIALIDADES

Descubra lo que nos hace grandes

We have developed the new generation PREP atomizing systems targeted at the demands of metal powders for Additive Manufacturing, Hot Isostatic Process, High-end Powder Metallurgy, Surface Technology, etc.

And we are developing the world’s first vertical commercial PREP atomizing system.

And we have also developed more than 60 different compositions of high-quality spherical metal powders, some of them are quite new material types.

Amplia experiencia

Con más de 10 años de experiencia en la industria de fabricación aditiva, podemos ofrecer varios productos de toda la cadena industrial para satisfacer sus necesidades...

selección completa

We provide a complete selection of PREP atomizing technology and powder bed SEBM 3D printing technology, including PREP equipment, PREPed Metal Powders, SEBM equipment, SEBMed components.

Desarrollo continuo

We offer continuous development and investment on PREP atomizing technology and powder bed SEBM 3D printing technology. And we are constantly updating our technologies, products and services.

Servicio al Cliente

We prioritize the needs of our customers. We are always at your service before, during, and after the sales.

Personalización del producto

For PREPed metal powders, we can provide the production of customized metal powders or manufacturing the metal powders with the raw materials provided by customers, whatever small batch or series production with the reasonable cost.

Explora más

Para obtener más información sobre nuestros productos, continúe leyendo...

Contáctenos para un excelente servicio y calidad

Looking for a professional additive manufacturing supplier and getting the newest quotations for our PREP atomizing system, or have any other questions, please click the button and leave us messages.

Blog más reciente

A new nickel based high-temperature alloy with comprehensive optimization design that combines formability and mechanical properties for additive properties

In order to achieve effective design of additive manufacturing nickel-base high-temperature alloys with good usability, a new type of nickel-base high-temperature alloy was developed by combining effective component screening and local element segregation, which has excellent formability, wide process applicability,

The successful application of SEBM additive manufacturing technology on medical parts

SEBM additive manufacturing technology is one of PBF technologies, which use electronic beam as heating resource. The principle is to use high-energy electron beams to scan and heat the metal powders at high speed under vacuum protection, melt layer by