LED BY PASSIONATE EXPERTS

The Leading of Additive Manufacturing

We have been maximizing the levels of the critical manufacturing environment, and we have successfully developed PREP atomizing system, SEBM 3D printing system and more than 60 grades of high-quality spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, and CoCrMo, etc.

Years Of Manufacturing

Experience

Continuous high quality and innovation

We rely on the innovation platform of State Key Laboratory of Porous Metal Materials to establish a joint innovation center for Metal Additive Manufacturing since 2010, and carry out the science and technology innovations of Additive Manufacturing jointly with high-level scientific research institutions and well-known experts at home and abroad.

We start the commercial production of PREP atomizing system and SEBM printing system since 2013 with high quality requirements.

ABOUT Truer

We are Professional In Additive Manufacturing

We specializes in R&D, Production, Sales and Technical Service of Plasma Rotating Electrode atomization equipment (PREP) & high-quality spherical PREPed metal powders, and Powder Bed Selective Electron Beam Melting 3D printing equipment (SEBM) & SEBMed components.

Lean production line

We have a modern production line, high-efficiency equipment, and skilled experts, which can meet the needs of customers all over the world.

Research & Innovation

We have an independant, energic, cooperative and innovative team for continuous research and development. We make the annual investment for research, development and new innovations.

- Developed a new generation of PREP atomizing equipment for the demands of Additivie Manufacturing, HIP, High-end Powder Metallurgy, Surface Technology, etc.

- Taking the leading in realizing vertical PREP atomizing systems in the world.

- Developed more than 60 kinds of high-quality spherical metal powder.

- The first to launch the commercial SEBM 3D printing systems (PBF) in China.

- Developed hundreds of lightweight, complex, high-performace metal components with our SEBM system.

- Provided more than 10,000 pieces of customized orthopedic implant materials to more than 20 authoritative hospitals in China

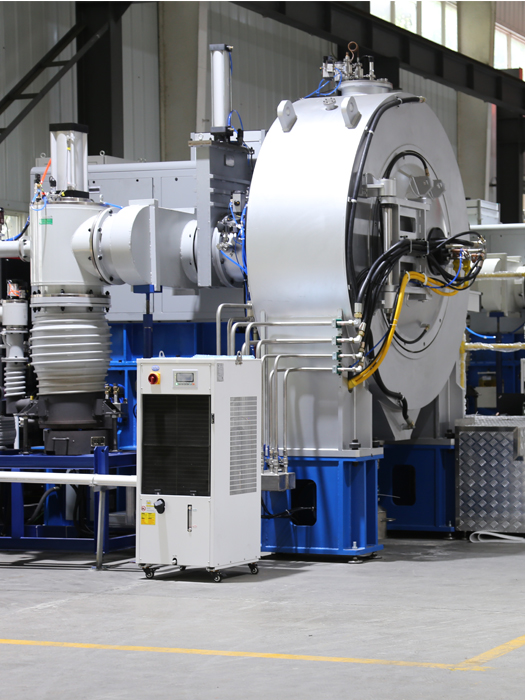

SLPA-N50

The medium-scale PREP system (SLPA-N50,Medium-sized) is purposely designed for continuous, industrial mass production of high-quality spherical metal powders.

Target groups:

The users who make the continuous, industrial production of high-quality spherical metal powders.

SLPA-D30

The small-scale PREP system (SLPA-D, desktop level) is purposely designed for R&D of novel alloy powders and small batch production of high-quality powders.

Target groups:

Scientific research, experiment, development and production of high-quality spherical metal powder in universities and research institutes (especially suitable for the new materials).

SLPA-N75

The large-scale PREP equipment (SLPA-N75) is purposely designed for continuous, industrial mass production of high quality spherical Titanium alloy powders.

Target groups:

High-quality and large-scale industrial production of spherical Ti-alloys powder users, and the powders can be used for mass production of parts in the fields of additive manufacturing, high-end powder metallurgy, laser cladding, etc.

Principle of Plasma Rotating Electrode Process (PREP)

The high-temperature plasma torch melts one end face of the high-speed rotating electrode rod, then the molten metal liquid film flies out and breaks into droplets under the action of centrifugal force generated by high-speed rotation. Some droplets will collide with inert gas molecules and break into smaller droplets. All these droplets are gradually solidified under the action of surface tension during flight and become spherical, and finally they reach the wall of the atomization chamber and are cooled into spherical metal powders.

Why truer

Let's Trust Truer and Work with Truer

We are committed to providing the suitable plasma rotating electrode atomization metal powder making equipment/system or high-quality PREP metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc.

We will continue to invest in R&D to optimize our PREP atomizing system together with production process parameters, to provide customers with the best quality, high-end metal powders to support customers to achieve the required high-performance components finally.

Quality is the Highest Priority

We continuously monitor each stage of the manufacturing processes and conduct the required testing before delivery to ensure that the products can meet customers' requirements.

Complete Industry Certification

We hold more than 100 patents in 3D printing areas and have led the development of national and industry standards many times.

OUR SPECIALTIES

Find Out What Makes Us Great

We have developed the new generation PREP atomizing systems targeted at the demands of metal powders for Additive Manufacturing, Hot Isostatic Process, High-end Powder Metallurgy, Surface Technology, etc.

And we are developing the world’s first vertical commercial PREP atomizing system.

And we have also developed more than 60 different compositions of high-quality spherical metal powders, some of them are quite new material types.

Extensive Experience

With 10+years experiences on Additive Manufacturing industry, we can offer various products of the whole industry chain to satisfy your requirements......

complete selection

We provide a complete selection of PREP atomizing technology and powder bed SEBM 3D printing technology, including PREP equipment, PREPed Metal Powders, SEBM equipment, SEBMed components.

Continuous Development

We offer continuous development and investment on PREP atomizing technology and powder bed SEBM 3D printing technology. And we are constantly updating our technologies, products and services.

Customer Service

We prioritize the needs of our customers. We are always at your service before, during, and after the sales.

Product Customization

For PREPed metal powders, we can provide the production of customized metal powders or manufacturing the metal powders with the raw materials provided by customers, whatever small batch or series production with the reasonable cost.

Explore More

To find out more about our products, please continue reading...

Contact Us For Excellent Service & Quality

Looking for a professional additive manufacturing supplier and getting the newest quotations for our PREP atomizing system, or have any other questions, please click the button and leave us messages.

Newest Blog

A new nickel based high-temperature alloy with comprehensive optimization design that combines formability and mechanical properties for additive properties

In order to achieve effective design of additive manufacturing nickel-base high-temperature alloys with good usability, a new type of nickel-base high-temperature alloy was developed by combining effective component screening and local element segregation, which has excellent formability, wide process applicability,

The successful application of SEBM additive manufacturing technology on medical parts

SEBM additive manufacturing technology is one of PBF technologies, which use electronic beam as heating resource. The principle is to use high-energy electron beams to scan and heat the metal powders at high speed under vacuum protection, melt layer by