Adapted from B01, Issue 23, 2023 of World Metal Herald

Background

As is well known, due to its excellent high-temperature strength, molybdenum metal has become an indispensable raw material in many industries. In practical applications, sometimes complex shaped components are required, but they are not easy to manufacture. Generally speaking, 3D printing technology can solve the manufacturing problems of complex components such as heat exchangers. When using molybdenum metal for 3D printing, the produced parts often have certain defects. In order to solve these defect problems, molybdenum+titanium carbide metal based composite powder was produced through the alloying effect of titanium carbide, which resulted in a turning point in the 3D printing effect. For example, using molybdenum titanium carbide to make complex shaped prototype devices such as heat exchangers is something that cannot be achieved by any other conventional manufacturing method.

Advantages of Molybdenum and its Alloys

In the next 30 years, it is expected that the global demand for electricity will double from the current level. To avoid the worst impacts of climate change, carbon dioxide emissions must be reduced below current levels while expanding energy production. There will be various solutions to increase power supply without increasing emissions, but mainly by raising the operating temperature inside the power generation equipment to improve its efficiency. For example, raising the temperature inside a nuclear reactor from 900 ℃ to 1000 ℃ would increase efficiency by 10%.

Although this change is beneficial for reducing emissions and lowering costs, it poses a challenge in the field of materials science: only a few materials can be used as candidate materials for manufacturing power generation equipment that operates at high temperatures. The melting point of molybdenum (2622 ℃) is the highest among existing metal elements. The high temperature that molybdenum metal and molybdenum based alloys can withstand will cause deformation or melting of other materials. Most importantly, it can maintain its shape and strength even at high temperatures. Although metals such as rhenium and niobium can also withstand extreme temperatures, they are far less abundant in natural resource reserves than molybdenum and are expensive, which may pose supply risks. Molybdenum metal is sometimes used in conjunction with carbon composite materials, providing higher stability at high temperatures. However, the design and manufacturing costs of carbon composite materials are high and time-consuming, so the scientific community still considers molybdenum metal as a solution, but it also has certain problems.

The transformation of manufacturing methods

Currently, in highly specialized industrial fields, an increasing number of components are produced through additive manufacturing (AM), also known as 3D printing. Additive manufacturing originated in the mid-1980s with the aim of accelerating the development of product prototypes. Its technological feature is to fuse multiple layers of materials together at the microscopic level. The printer produces precise replicas through layer by layer molding based on a computer 3D model.

Unlike traditional subtractive manufacturing processes such as milling, cutting, drilling, and grinding, additive manufacturing produces almost no waste. Usually, it is only necessary to modify the design scheme on the computer, so using additive manufacturing to produce complex shaped components is more cost-effective. Some designs that are difficult or even impossible to achieve with traditional manufacturing processes, such as components with hollow parts, can be realized through 3D printing.

The complex shaped components required by the aerospace, defense, and energy industries can be 3D printed using molybdenum metal, which can improve thermal efficiency and generate more electricity with fewer resources. However, one of the drawbacks faced by 3D printed molybdenum metal components is the possibility of losing their mechanical properties and stability, making them unusable. This is because under inappropriate printing conditions, 3D printed parts of molybdenum metal and molybdenum based alloys are prone to defects such as pores and cracks.

However, by precisely controlling the 3D printing process, it is possible to produce parts with uniform and stable performance, high-quality and crack free using molybdenum metal and molybdenum based alloys (such as titanium carbide molybdenum based alloys). At present, Oak Ridge National Laboratory in the United States is collaborating with relevant parties to conduct large-scale trial production of molybdenum metal and molybdenum based alloy components.

Potential additive manufacturing methods

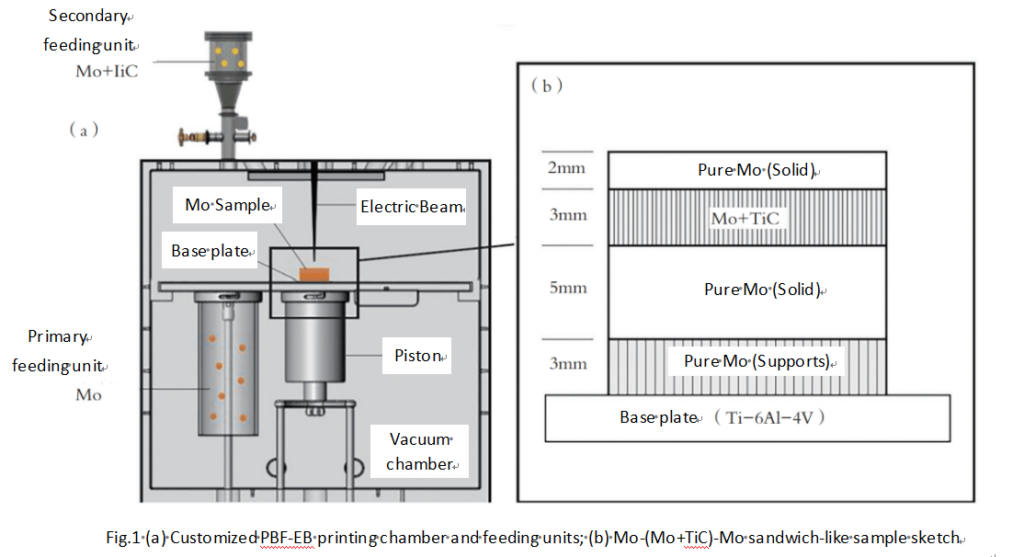

This manufacturing process uses an additive manufacturing method called “Powder Bed Melting (PBF)” (see Figure 1) to melt powdered materials into solids. PBF requires the use of lasers or electron beams to melt and fuse powdered materials, and researchers have employed the latter method to better control temperature changes during the printing process. Due to the easy occurrence of defects in molybdenum metal during processing, the related PBF process has not yet been successful on a commercial scale, but recent research suggests that this situation may soon improve.

Recently, researchers have confirmed that PBF-EB technology can produce high-quality molybdenum metal with unique grain structure, which cannot be achieved by traditional molybdenum metal manufacturing routes. The advancement of PBF-EB technology enables molybdenum metal to be successfully printed into structural components used in nuclear thermal propulsion systems.

It was reported that Molybdenum components were successfully printed with our equipment (SEBM-Y150 et SEBM-T200) and raw material powders produced by our PREP equipment (SLPA-D30) and used for testing by our clients.

Other reports

In addition to molybdenum metal, researchers have also successfully produced molybdenum+titanium carbide metal based composite powders, known as “metal ceramics” in materials science terminology. In order to manufacture this metal ceramic, researchers mechanically alloyed 60% molybdenum powder and 40% titanium carbide raw material powder, and printed the formed parts without detecting any defects. The successful production of such materials has the potential to drive progress in energy systems that require materials to operate in extreme environments, such as supercritical carbon dioxide.

Other research teams have also achieved gratifying results. In 2019, Beijing Institute of Technology developed 3D printed molybdenum metal components for ion thrusters used in the aerospace industry. The research team also combined molybdenum metal powder and titanium carbide powder together to form a stable and antioxidant composite material. This composite method has produced positive results, not only applicable to pure molybdenum metal, but also to other molybdenum alloys. A research team in Singapore mixed titanium diboride nanoparticles with nickel based alloy Inconel 625 containing molybdenum, which also produced good printability. These developments further demonstrate the feasibility of significantly improving the 3D printing of molybdenum metal and molybdenum containing alloy components in the future. These projects showcase the unique properties of molybdenum and its increasing value in the global decarbonization process.

The improvement of efficiency in thermal power plants such as nuclear reactors depends on the development of high-quality materials, especially those with high temperature strength. Molybdenum can be said to be the best candidate material for related applications. The ability to use 3D printing technology to print materials into industrial shapes will help reduce resource consumption and generate more electricity in the future.