DIRIGÉ PAR DES EXPERTS PASSIONNÉS

Le leader de la fabrication additive

We have been maximizing the levels of the critical manufacturing environment, and we have successfully developed PREP atomizing system, SEBM 3D printing system and more than 60 grades of high-quality spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, and CoCrMo, etc.

Années de fabrication

Vivre

Haute qualité et innovation continues

Nous nous appuyons sur la plate-forme d'innovation du State Key Laboratory of Porous Metal Materials pour établir un centre d'innovation conjoint pour la fabrication additive métallique depuis 2010, et réaliser les innovations scientifiques et technologiques de la fabrication additive conjointement avec des institutions de recherche scientifique de haut niveau et bien connu experts à la maison et à l'étranger.

We start the commercial production of PREP atomizing system and SEBM printing system since 2013 with high quality requirements.

À PROPOS

We are Professional In Additive Manufacturing

We specializes in R&D, Production, Sales and Technical Service of Plasma Rotating Electrode atomization equipment (PREP) & high-quality spherical PREPed metal powders, and Powder Bed Selective Electron Beam Melting 3D printing equipment (SEBM) & SEBMed components.

Ligne de production allégée

Nous disposons d'une ligne de production moderne, d'équipements à haut rendement et d'experts qualifiés, capables de répondre aux besoins des clients du monde entier.

Recherche & Innovation

Nous avons une équipe indépendante, énergique, coopérative et innovante pour une recherche et un développement continus. Nous faisons l'investissement annuel pour la recherche, le développement et les nouvelles innovations.

- Developed a new generation of PREP atomizing equipment for the demands of Additivie Manufacturing, HIP, High-end Powder Metallurgy, Surface Technology, etc.

- Taking the leading in realizing vertical PREP atomizing systems in the world.

- Developed more than 60 kinds of high-quality spherical metal powder.

- The first to launch the commercial SEBM 3D printing systems (PBF) in China.

- Developed hundreds of lightweight, complex, high-performace metal components with our SEBM system.

- Provided more than 10,000 pieces of customized orthopedic implant materials to more than 20 authoritative hospitals in China

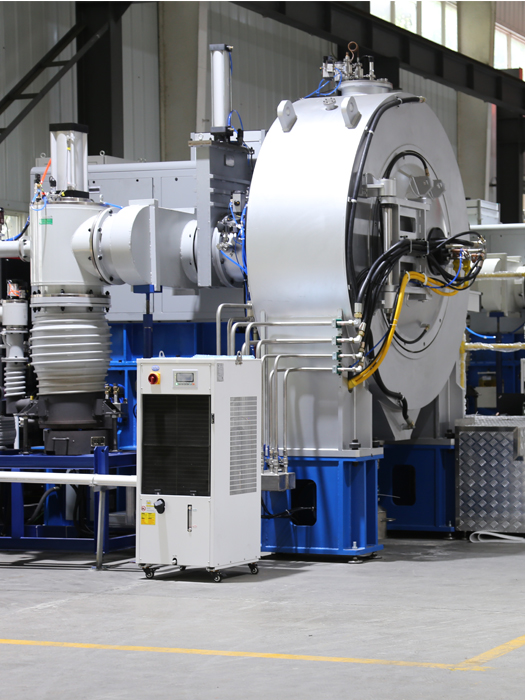

SLPA-N50

The medium-scale PREP system (SLPA-N50,Medium-sized) is purposely designed for continuous, industrial mass production of high-quality spherical metal powders.

Groupes cibles:

Les utilisateurs qui réalisent la production industrielle continue de poudres métalliques sphériques de haute qualité.

SLPA-D30

Le système PREP à petite échelle (SLPA-D, niveau bureau) est spécialement conçu pour la R&D de nouvelles poudres d'alliage et la production en petits lots de poudres de haute qualité.

Groupes cibles:

Recherche scientifique, expérimentation, développement et production de poudre métallique sphérique de haute qualité dans les universités et les instituts de recherche (particulièrement adaptés aux nouveaux matériaux).

SLPA-N75

The large-scale PREP equipment (SLPA-N75) is purposely designed for continuous, industrial mass production of high quality spherical Titanium alloy powders.

Target groups:

High-quality and large-scale industrial production of spherical Ti-alloys powder users, and the powders can be used for mass production of parts in the fields of additive manufacturing, high-end powder metallurgy, laser cladding, etc.

Principe du processus d'électrode rotative au plasma (PREP)

La torche à plasma à haute température fait fondre une face d'extrémité de la tige d'électrode rotative à grande vitesse, puis le film liquide de métal en fusion s'envole et se brise en gouttelettes sous l'action de la force centrifuge générée par la rotation à grande vitesse. Certaines gouttelettes entreront en collision avec des molécules de gaz inerte et se briseront en gouttelettes plus petites. Toutes ces gouttelettes se solidifient progressivement sous l'action de la tension superficielle pendant le vol et deviennent sphériques, et finalement elles atteignent la paroi de la chambre d'atomisation et sont refroidies en poudres métalliques sphériques.

Pourquoi plus vrai

Faisons confiance à Truer et travaillons avec Truer

We are committed to providing the suitable plasma rotating electrode atomization metal powder making equipment/system or high-quality PREP metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc.

We will continue to invest in R&D to optimize our PREP atomizing system together with production process parameters, to provide customers with the best quality, high-end metal powders to support customers to achieve the required high-performance components finally.

La qualité est la priorité absolue

We continuously monitor each stage of the manufacturing processes and conduct the required testing before delivery to ensure that the products can meet customers' requirements.

Certification complète de l'industrie

We hold more than 100 patents in 3D printing areas and have led the development of national and industry standards many times.

NOS SPÉCIALITÉS

Découvrez ce qui nous rend formidables

We have developed the new generation PREP atomizing systems targeted at the demands of metal powders for Additive Manufacturing, Hot Isostatic Process, High-end Powder Metallurgy, Surface Technology, etc.

And we are developing the world’s first vertical commercial PREP atomizing system.

And we have also developed more than 60 different compositions of high-quality spherical metal powders, some of them are quite new material types.

Une vaste expérience

Avec plus de 10 ans d'expérience dans l'industrie de la fabrication additive, nous pouvons proposer divers produits de toute la chaîne de l'industrie pour satisfaire vos exigences ......

sélection complète

We provide a complete selection of PREP atomizing technology and powder bed SEBM 3D printing technology, including PREP equipment, PREPed Metal Powders, SEBM equipment, SEBMed components.

Développement continu

We offer continuous development and investment on PREP atomizing technology and powder bed SEBM 3D printing technology. And we are constantly updating our technologies, products and services.

Service Clients

We prioritize the needs of our customers. We are always at your service before, during, and after the sales.

Personnalisation de produit

For PREPed metal powders, we can provide the production of customized metal powders or manufacturing the metal powders with the raw materials provided by customers, whatever small batch or series production with the reasonable cost.

Explore plus

Pour en savoir plus sur nos produits, continuez à lire...

Contact Us For Excellent Service & Quality

Looking for a professional additive manufacturing supplier and getting the newest quotations for our PREP atomizing system, or have any other questions, please click the button and leave us messages.

Blog le plus récent

The preparation and research of Spherical Molybdenum Powder for 3D Printing prepared by Plasma Rotating Electrode Process

By Shanghai Truer Background Molybdenum has excellent properties such as high temperature strength, good electrical and thermal conductivity, good heat and fatigue resistance, and low toxicity. It is used in aerospace, nuclear industry, electronics industry, and medical fields. However, its

The Application of Molybdenum and its alloys on 3D printing

Adapted from B01, Issue 23, 2023 of World Metal Herald Background As is well known, due to its excellent high-temperature strength, molybdenum metal has become an indispensable raw material in many industries. In practical applications, sometimes complex shaped components are