In order to achieve effective design of additive manufacturing nickel-base high-temperature alloys with good usability, a new type of nickel-base high-temperature alloy was developed by combining effective component screening and local element segregation, which has excellent formability, wide process applicability, and low defect density. Through first principles calculations and experimental characterization, it has been confirmed that controlling the distribution of Boron (B) at the interface of MC carbides and γ phase matrix can effectively suppressing the formation of cracks induced by Boron (B) segregation. Meanwhile, the mechanical properties of this alloy are comparable or even superior to existing traditional high-temperature alloys. This method solves the problem of element segregation in additive manufacturing process and can be extended to control the distribution of other key elements, providing a new approach for designing new Ni high-temperature alloys with printability and balanced mechanical properties.

Edited from “Robust additive manufacturable Ni superalloys designed by the integrated optimization of local elemental segregation and cracking susceptibility criteria”on 《Acta Materialia》

Ni-base high-temperature alloys, which can be used in aviation and aerospace applications, have become potential materials for additive manufacturing (AM), and the components produced have complex geometric shapes and sizes. However, high cooling rates and spatially variable temperature gradients during additive manufacturing often lead to severe cracking, making the production of Ni-base high-temperature alloy high-density components still challenging. At present, most of the existing Ni-base high-temperature alloys are designed and optimized based on traditional manufacturing methods, and are not fully suitable for the metallurgical conditions of additive manufacturing. Therefore, it is necessary to develop new alloy compositions suitable for AM conditions.

Among all the critical elements that are prone to segregation, B has attracted widespread attention. According to reports, the addition of a small amount of B can strongly promote AM cracking, as uncontrolled B segregation at grain boundaries inevitably leads to the formation of low melting point borides. These borides are easily transformed into liquid films near the solidification state or during the reheating stage, causing cracks.

Introducing high-energy boundaries to control boron segregation is expected to be effective. In addition to grain boundaries, phase boundaries are another form of high-energy boundary that can be used to adjust the distribution of B, including the interfaces of MC carbides/ γ、 M23C6 carbide/ γ, etc. By controlling the formation of primary phase boundaries in MC carbides, B atoms can exist at the MC/matrix interface without causing aggregation to form borides and trigger cracks. Therefore, it is necessary to choose an appropriate type of MC carbide to control the distribution of B.

In order to achieve effective design for additive manufacturing of nickel high-temperature alloys, Professor Xu Wei’s research group at Northeastern University has proposed a mixed alloy design strategy. A hybrid design model has been developed by combining the strategy of adjusting local element distribution with a scheme of minimizing crack sensitivity using nominal chemical composition. It can effectively design a new type of Ni high-temperature alloy with good formability and a wide process window, which has good thermal mechanical properties in practical applications.

Combining the introduced γ / A new alloy AMSC-DB was developed based on NbC phase boundaries and optimized crack sensitivity criteria. The high robustness of processing parameters in preparing low defect density bulk samples confirms its excellent formability, and no B clusters were observed, but enriched along the matrix/NbC phase boundary. Therefore, the cracking caused by boron segregation in AMSC-DB alloy can be effectively suppressed. Meanwhile, the newly designed AMSC-DB alloy exhibits a good balance of strength and ductility at room and high temperatures, as well as appropriate oxidation resistance, which is comparable or even better than traditional high-temperature alloys.

Due to the uncontrollable segregation of B in the benchmark alloy AMS-nDB, microcracks related to Cr2B were observed in the interdendritic zone. The difference in printability between AMS-NDB and AMSC-DB alloys can effectively validate the feasibility of boron B distribution strategies. The method of using phase boundaries to spatially control the distribution of elements may also be applied to other key minority elements, providing a new approach for designing new additive manufacturing nickel high-temperature alloys.

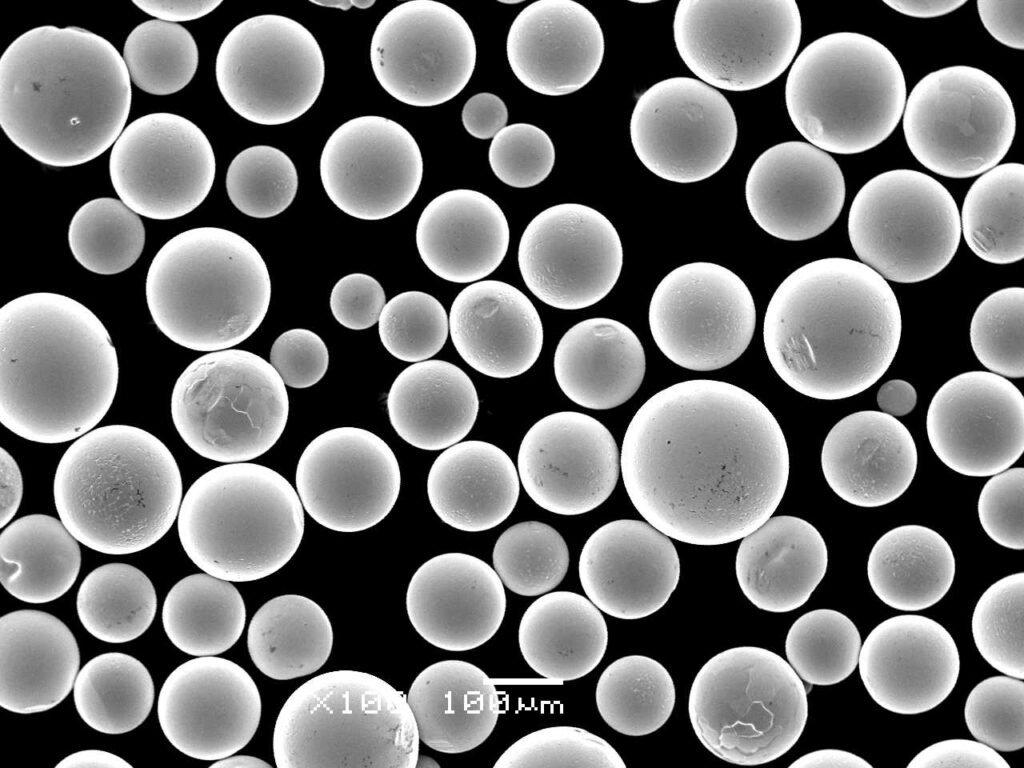

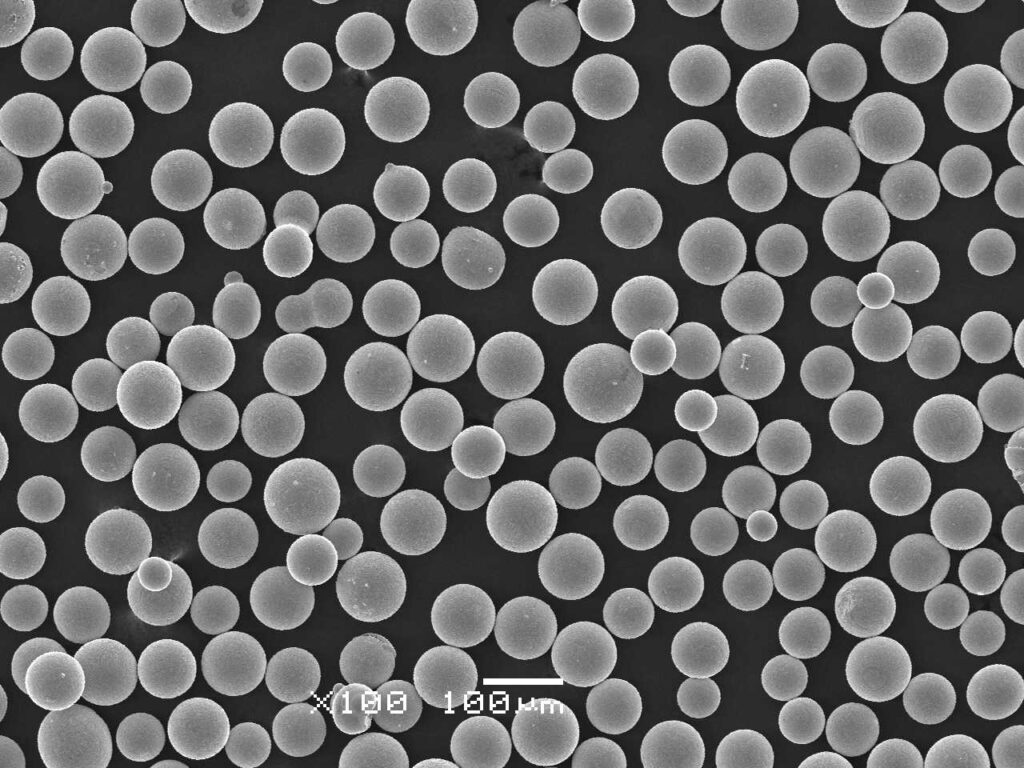

Plasma Rotating Electrode Process (PREP) can provide high-quality spherical metal powders with less satilite and pore powders, which are very good for Additive manufacturing. Shanghai Truer can provide both the suitable PREP atomizing equipment and high quality spherical metal powders produced by our PREP equipment to meet different customers’ requirements, such as new material development, series production, etc.

Shanghai Truer takes the lead in providing the innovative desktop level PREP atomizing equipment (SLPA-D30) globally, for which the rotating speed of consumable electrode rods can be up to 50,000rpm, and it is very suitable for preparation of small batch , multi variety and high quality metal powders. Using this equipment, we and our customers have successfully developed more 100 different compositions of high quality spherical metal powders, such as TiNi, TiTa, TiAl, TiNbZr, CoCrMo, HEA, etc. In addition, we also provide the medium-scale PREP equipment (SLPA-N50, which is specifically developed for Ni-base super-alloys) and large-scale PREP equipment (SLPA-N75, which is developed for Ti-base alloys), and both are suitable for industrial production and can provide high quality spherical metal powders with reasonable cost for 3D printing and other applications.

Principle of Plasma Rotating Electrode Process (PREP)

The high-temperature plasma torch melts one end face of the high-speed rotating electrode rod (raw materials), then the molten metal liquid film flies out and breaks into droplets under the action of centrifugal force generated by high-speed rotation. Some droplets will collide with inert gas molecules and break into smaller droplets. All these droplets are gradually solidified under the action of surface tension during flight and become spherical, and finally they reach the wall of the atomizing chamber and are cooled into spherical metal powders.

Small-scale PREP system: SLPA-D30

The small-scale PREP system (SLPA-D30, desktop level) is purposely designed for R&D of novel alloy powders and small batch production of high quality powders with the following characteristics:

ü Relatively lower cost for multi-small-batch production

ü Quicker switch for multi-small-batch and diversified powder production (time reduction)

ü Ergonomics friendly, easy to operate

ü Simple and professional man-machine interface design

ü High fine powders output rate due to high rotating speed (up to 50,000rpm)

ü The produced powders have high sphericity (over 95%) and high quality, such as low porosity powders, low satellite powders, high purity (low oxygen increase,≤100ppm) due to atomizing in the inert protection atmosphere.

ü Can produce nearly all metal powders which rods are electro-conductive, specially for refractory metals, high-activity metals, super-alloys, etc.

Main Technical Parameters and Structure

|

Main Technical Parameters |

|

|

Rotating speed of electrode rod |

Up to 50,000rpm (Adjustable) |

|

Diameter of Eletrode rod |

Φ30mmx160mm |

|

Powder Morphology |

Spherical Rate ≥95% |

|

Particle Size Distribution |

D50≤43µm (Inconel 718) |

|

Capacity |

≥10kg (8hrs, Inconel 718) |

|

Oxygen Increment |

≤100ppm (Ti6Al4V ≤100ppm; Inconel 718 ≤50ppm) |

|

Atmosphere |

Ar or He (high purity) or other inert gas |

|

Maximum power |

120kW |

|

Machine size |

4m x 3m x 2.5m |

|

Applications |

Ti&Alloys, Ni&Alloys, Co&Alloys, Stainless steels, high entropy alloys, Cu& Alloys and refractory alloys |

Medium-scale PREP system: SLPA-N50

The medium-scale PREP system (SLPA-N50) is purposely designed for continuous, industrial mass production of high quality spherical metal powders with the following characteristics:

ü Reasonable cost for medium-batch production

ü Ergonomics friendly, easy to operate

ü Simple and professional man-machine interface design

ü Relatively high fine powders output rate (average rotating speed: 30,000rpm)

ü The produced powders have high sphericity (over 90%) and high quality, such as low porosity powders, low satellite powders, high purity (low oxygen increase,≤120ppm) due to atomizing in the inert protection atmosphere.

ü Melting temperature ≥2600℃, suitable for produciton of Ti-alloys, Steels, Superalloys, Refractory alloys, high entropy alloys, etc.

Main Technical Parameters and Structure

|

Main Technical Parameters |

|

|

Rotating speed of electrode rod |

Average 30,000rpm (Adjustable) |

|

Diameter of Eletrode rod |

Φ50mmx260mm |

|

Powder Morphology |

Spherical Rate ≥95% |

|

Particle Size Distribution |

D50≤63µm (Ni-base superalloys) D50≤105µm (Ti-alloys) D50≤100µm (W-alloys) |

|

Capacity |

≥80kg (8h, Ni-base superalloys) ≥40kg (8h, Ti-alloys) ≥100kg (8h, W-alloys) |

|

Oxygen Increment |

≤120ppm |

|

Atmosphere |

Ar or He (high purity) or other inert gas |

|

Maximum power |

260kW |

|

Machine size |

6m x 6m x 5m |

|

Applications |

Ti&Alloys, Ni&Alloys, Co&Alloys, Stainless steels, high entropy alloys, Cu& Alloys and refractory alloys, etc. |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.