Ti Alloy Powders

Ti Alloy Powders

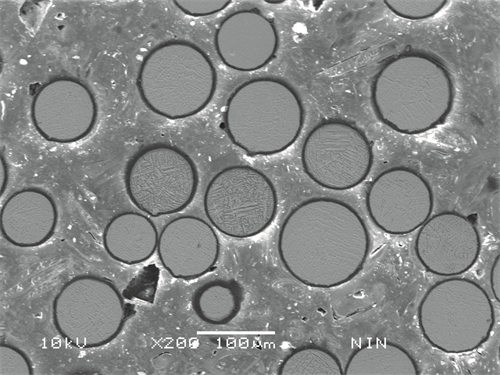

Our PREP system can manufacture highly spherical, good flowability, high-purity Titanium alloy powders, such as Ti-6Al-4V grade 23 (TC4 ELI), TA15, Ti-48Al-2Cr-2Nb, Ti22Al25Nb, Ti45Al8Nb, etc, to support the production of high-quality components and sub-assemblies for the fields of Aerospace, Petrochemical industry, Biomedicine, Marine ships, and Industrial markets, such as Aircraft lightweight structural components, Automobile lightweight structural components, human implants, Corrosion-resistance components on marine ship or petrochemical field, etc.

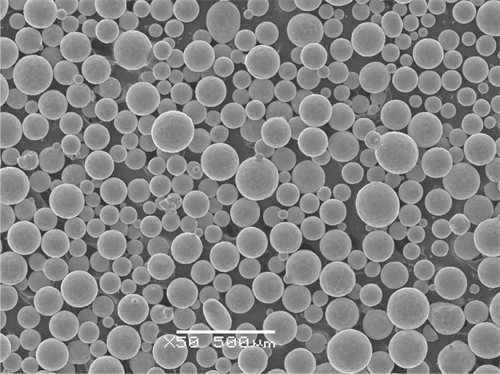

High-quality Spherical Metal Powder – TA15

- Oxygen (wt%): 0.09-0.12

- Particle Size: 20-250μm

- Flowability (s/50g): 20-35

Applicable Production Process: Additive manufacturing (SLM, SEBM, LDM, WAAM, Laser cladding, etc), HIP, Coating technology, High-end Powder Metallurgy, etc.

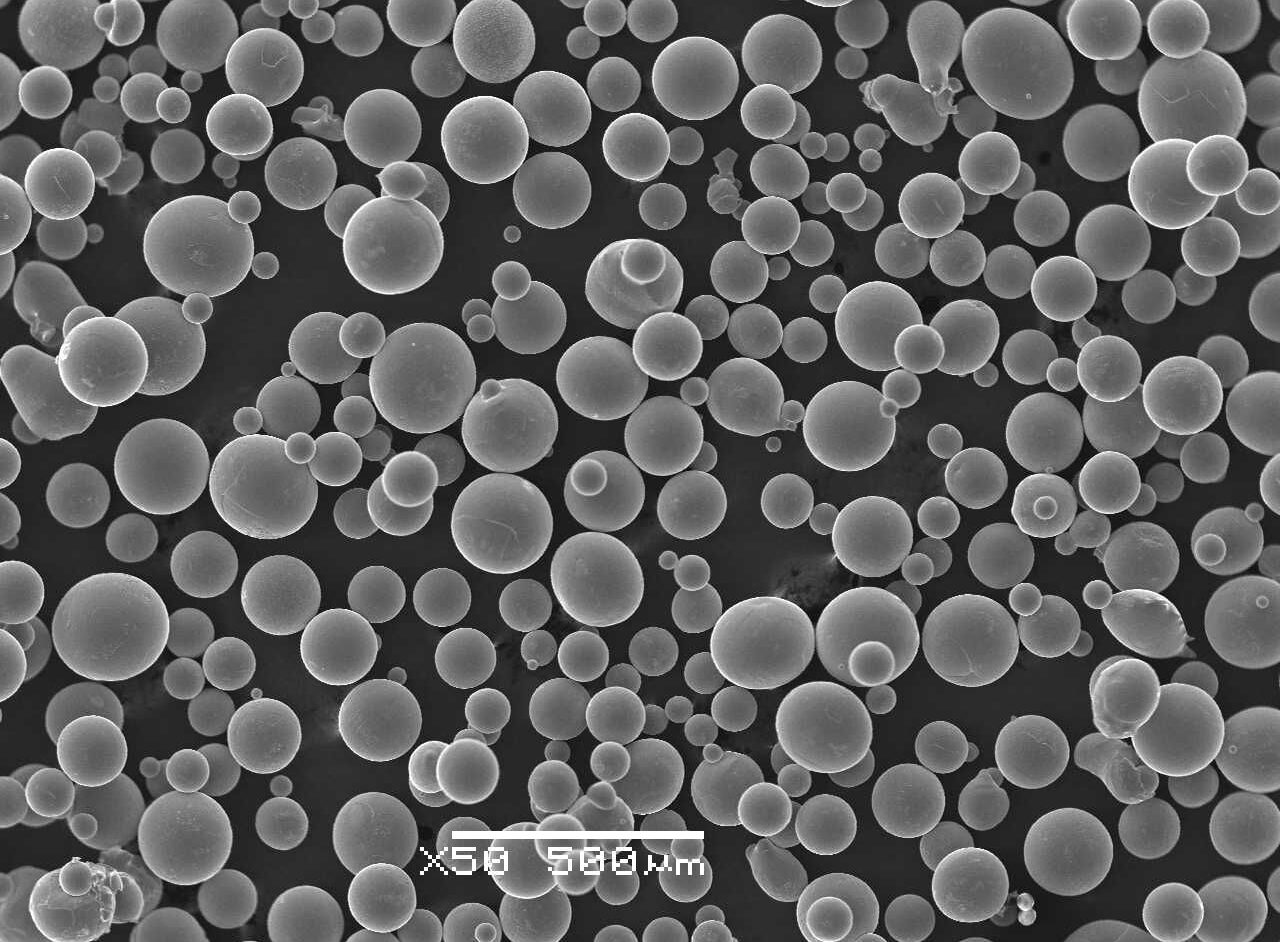

High-quality Spherical Metal Powder – Ti-6Al-4V (TC4)

- Oxygen (wt%): 0.06-0.15

- Particle Size: 15-300μm

- Flowability (s/50g): 18-25

- Applicable Production Process: Additive manufacturing (SLM, SEBM, LDM, WAAM, Laser cladding, etc), HIP, Coating technology, High-end Powder Metallurgy, etc.

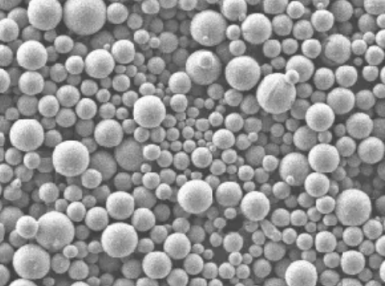

High-quality Spherical Metal Powder – Ti-45Al-8Nb

- Oxygen (wt%): 0.06-0.15

- Particle Size: 10-150μm

- Flowability (s/50g): 18-35

- Applicable Production Process: Additive manufacturing (SLM, SEBM, LDM, WAAM, Laser cladding, etc), HIP, Coating technology, High-end Powder Metallurgy, etc.

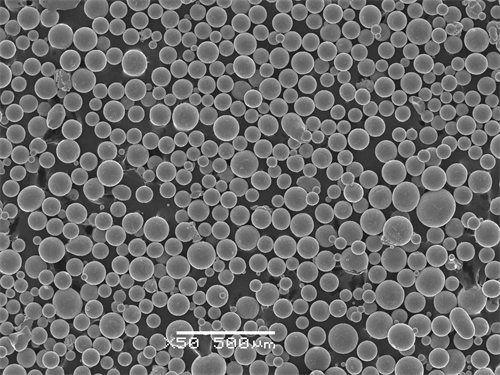

High-quality Spherical Metal Powder – Ti-48Al-2Cr-2Nb

- Oxygen (wt%): 0.06-0.12

- Particle Size: 10-150μm

- Flowability (s/50g): 18-35

- Applicable Production Process: Additive manufacturing (SLM, SEBM, LDM, WAAM, Laser cladding, etc), HIP, Coating technology, High-end Powder Metallurgy, etc.