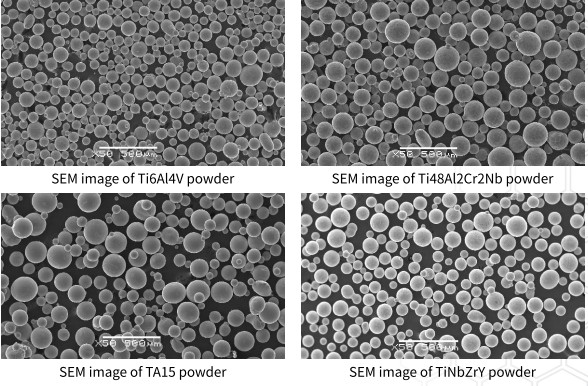

Titanium alloy powder and titanium aluminum alloy powders are a common class of metal materials used for 3D printing. The metal powders made by PREP are widely used in the aerospace, biomedical, and automotive industries.

Titanium alloy powder for 3D Printing

Titanium alloy has high specific strength, good corrosion resistance, and low-temperature resistance, and is mostly used in the manufacture of various pressure vessels, such as frames, rocket shells, etc. According to statistics, the proportion of titanium alloys used in passenger aircraft fuselages reaches 20%, and the proportion of military aircraft fuselages will reach 50%. Among them, Ti-6Al-4V belongs to the (α+β) type titanium alloy, which has the advantages of both α and β titanium alloy, with high specific strength, high thermal strength, and good comprehensive mechanical properties, widely used in the manufacture of aircraft blades, compressor discs, and aero-engine fuel storage, etc.

Metal additive manufacturing technologies are divided into two main categories: Powder bed fusion (PBF) and directed energy deposition (DED).

Powder bed fusion is divided into Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) depending on the heat source. Energy deposition techniques are divided into Laser Engineered Net Shaping, LENS and Electron Beam Fabrication, EBF, depending on the heat source and raw material.

According to the available literature, 3D printing and forming of titanium alloys is mainly based on laser-selective melting technology, electron beam-selective melting technology and directed energy deposition technology, the parameters of these three metal 3D printing technologies are characterised as shown in the table below.

Properties of Common Titanium Alloy 3D Printing Technologies

| Parameters | SLM | SEBM | DED |

| Printing Size | Limited, smaller | Limited, smaller | Larger |

| Beam Spot Size | 0.1-0.5mm | 0.2-0.5mm | 2-4mm |

| Particle Size | <45μm | 45-105μm | 74-250μm |

| Thickness of layer | 30-100μm | 50-100μm | 500-1000μm |

| Print Efficiency | About 20-35 m³/h | About 55-80 m³/h | About 16-320 m³/h |

| Cleanliness of surface | Ra 9-12μm | Ra 25-35μm | Ra 20-50μm(concern about the beam spot size) |

| Residual stress | high | low | high |

| Heat treatment | relief annealing, recommend hot isostatic pressing | Hot isostatic pressing is available | Relief annealing, recommend hot isotatic pressing |

| Compositional Variation | None | Volatilisation of Al elements | None |

| Printing capacity | Thin-wall, hollow, tuss, etc. complex and fine structure | Thin-wall, hollow, tuss, etc. complex and fine structure | Relatively simple geometries |

| Restoration, remanufacturing capabilities | Limited(Flat-based remanufacturing) | None | None |

Areas of Application for 3D Printed Titanium Alloys

Aerospace and biomedical are two of the fastest-growing sectors and the areas where metal 3D printed parts are most effective.

Metal performance 3D printing technology was born mainly in the context of responding to the needs of aerospace technology again, and today the world’s major aerospace companies and research institutes are vigorously developing metal performance 3D printing technology. Therefore, both domestic and international 3D printing technologies have been announced to make aerospace needs the first industrial application target for 3D printing.

3D printing is also an important means of achieving personalised medicine and has gradually become a cutting-edge manufacturing technology that various countries are competing to develop. Medical models, surgical guides, and personalized orthopedic implants made using 3D printing technology are already widely used in clinical practice. Some of the applications of 3D printing in the medical field include acetabular cups, mandibles, and prostheses.

In addition to the aforementioned aerospace and biomedical fields, 3D printing is also widely used in automotive, moulds, electronics and other fields.

3D printing has advantages that traditional processes do not have. Traditional processes cannot even directly manufacture complete parts, 3D printing technology can be shaped and manufactured according to user design requirements and can achieve full life manufacturing and safeguarding of high performance metal parts and can be combined with traditional technologies to form compliant or combined manufacturing.

The above mainly introduces the properties and applications of titanium alloy powder commonly used for 3D printing. For more information about PREP titanium alloy powder (Ti-48Al-2Cr-2Nb, Ti-2Al-Nb, -Ti-45Al-8Nb) and PREP powder making equipment, please feel free to contact us.