GEFÜHRT VON LEIDENSCHAFTLICHEN EXPERTEN

Führend in der additiven Fertigung

We have been maximizing the levels of the critical manufacturing environment, and we have successfully developed PREP atomizing system, SEBM 3D printing system and more than 60 grades of high-quality spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, and CoCrMo, etc.

Jahre der Herstellung

Erfahrung

Kontinuierliche hohe Qualität und Innovation

Wir verlassen uns auf die Innovationsplattform des State Key Laboratory of Porous Metal Materials, um seit 2010 ein gemeinsames Innovationszentrum für Metal Additive Manufacturing einzurichten, und führen die wissenschaftlichen und technologischen Innovationen der Additiven Fertigung gemeinsam mit hochrangigen und bekannten wissenschaftlichen Forschungseinrichtungen durch Experten im In- und Ausland.

We start the commercial production of PREP atomizing system and SEBM printing system since 2013 with high quality requirements.

ÜBER Trueer

We are Professional In Additive Manufacturing

We specializes in R&D, Production, Sales and Technical Service of Plasma Rotating Electrode atomization equipment (PREP) & high-quality spherical PREPed metal powders, and Powder Bed Selective Electron Beam Melting 3D printing equipment (SEBM) & SEBMed components.

Schlanke Produktionslinie

Wir verfügen über eine moderne Produktionslinie, hocheffiziente Ausrüstung und qualifizierte Experten, die die Anforderungen von Kunden auf der ganzen Welt erfüllen können.

Forschung & Innovation

Wir haben ein unabhängiges, energisches, kooperatives und innovatives Team für kontinuierliche Forschung und Entwicklung. Wir tätigen die jährliche Investition für Forschung, Entwicklung und neue Innovationen.

- Developed a new generation of PREP atomizing equipment for the demands of Additivie Manufacturing, HIP, High-end Powder Metallurgy, Surface Technology, etc.

- Taking the leading in realizing vertical PREP atomizing systems in the world.

- Developed more than 60 kinds of high-quality spherical metal powder.

- The first to launch the commercial SEBM 3D printing systems (PBF) in China.

- Developed hundreds of lightweight, complex, high-performace metal components with our SEBM system.

- Provided more than 10,000 pieces of customized orthopedic implant materials to more than 20 authoritative hospitals in China

SLPA-N50

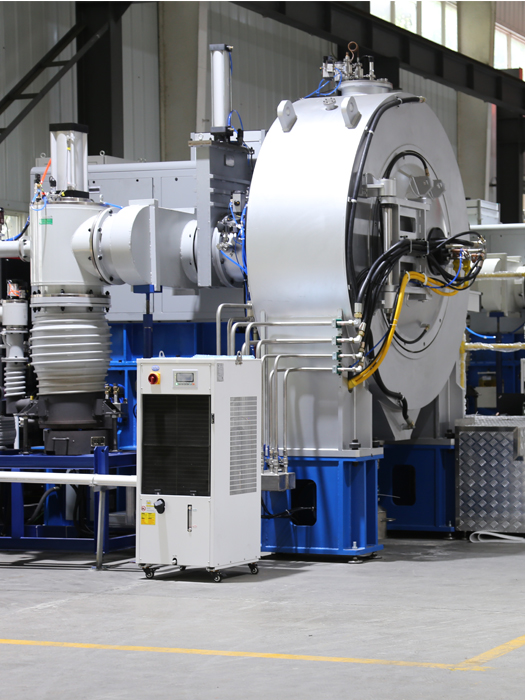

The medium-scale PREP system (SLPA-N50,Medium-sized) is purposely designed for continuous, industrial mass production of high-quality spherical metal powders.

Zielgruppen:

Die Anwender, die die kontinuierliche, industrielle Produktion von hochwertigen kugelförmigen Metallpulvern vornehmen.

SLPA-D30

Das kleine PREP-System (SLPA-D, Desktop-Level) wurde speziell für die Forschung und Entwicklung neuartiger Legierungspulver und die Kleinserienproduktion hochwertiger Pulver entwickelt.

Zielgruppen:

Wissenschaftliche Forschung, Experiment, Entwicklung und Produktion von hochwertigem kugelförmigem Metallpulver in Universitäten und Forschungsinstituten (besonders geeignet für die neuen Materialien).

SLPA-N75

The large-scale PREP equipment (SLPA-N75) is purposely designed for continuous, industrial mass production of high quality spherical Titanium alloy powders.

Target groups:

High-quality and large-scale industrial production of spherical Ti-alloys powder users, and the powders can be used for mass production of parts in the fields of additive manufacturing, high-end powder metallurgy, laser cladding, etc.

Prinzip des Plasma Rotating Electrode Process (PREP)

Der Hochtemperatur-Plasmabrenner schmilzt eine Endfläche des mit hoher Geschwindigkeit rotierenden Elektrodenstabs, dann fliegt der flüssige Film aus geschmolzenem Metall heraus und bricht unter der Wirkung der durch die Hochgeschwindigkeitsrotation erzeugten Zentrifugalkraft in Tröpfchen auf. Einige Tröpfchen kollidieren mit Inertgasmolekülen und zerfallen in kleinere Tröpfchen. Alle diese Tröpfchen verfestigen sich allmählich unter der Wirkung der Oberflächenspannung während des Fluges und werden kugelförmig, und schließlich erreichen sie die Wand der Zerstäubungskammer und werden zu kugelförmigen Metallpulvern abgekühlt.

Warum wahrer

Vertrauen wir Truer und arbeiten wir mit Truer zusammen

We are committed to providing the suitable plasma rotating electrode atomization metal powder making equipment/system or high-quality PREP metal powders to meet different customers’ requirements, i.e. new material development, or production of high-quality parts, etc.

We will continue to invest in R&D to optimize our PREP atomizing system together with production process parameters, to provide customers with the best quality, high-end metal powders to support customers to achieve the required high-performance components finally.

Qualität hat höchste Priorität

We continuously monitor each stage of the manufacturing processes and conduct the required testing before delivery to ensure that the products can meet customers' requirements.

Vollständige Branchenzertifizierung

We hold more than 100 patents in 3D printing areas and have led the development of national and industry standards many times.

UNSERE SPEZIALITÄTEN

Finden Sie heraus, was uns großartig macht

We have developed the new generation PREP atomizing systems targeted at the demands of metal powders for Additive Manufacturing, Hot Isostatic Process, High-end Powder Metallurgy, Surface Technology, etc.

And we are developing the world’s first vertical commercial PREP atomizing system.

And we have also developed more than 60 different compositions of high-quality spherical metal powders, some of them are quite new material types.

Langjährige Erfahrung

Mit mehr als 10 Jahren Erfahrung in der additiven Fertigungsindustrie können wir verschiedene Produkte der gesamten Industriekette anbieten, um Ihre Anforderungen zu erfüllen......

komplette Auswahl

We provide a complete selection of PREP atomizing technology and powder bed SEBM 3D printing technology, including PREP equipment, PREPed Metal Powders, SEBM equipment, SEBMed components.

Fortlaufende Entwicklung

We offer continuous development and investment on PREP atomizing technology and powder bed SEBM 3D printing technology. And we are constantly updating our technologies, products and services.

Kundendienst

We prioritize the needs of our customers. We are always at your service before, during, and after the sales.

Produktanpassung

For PREPed metal powders, we can provide the production of customized metal powders or manufacturing the metal powders with the raw materials provided by customers, whatever small batch or series production with the reasonable cost.

Erkunde mehr

Um mehr über unsere Produkte zu erfahren, lesen Sie bitte weiter...

Contact Us For Excellent Service & Quality

Looking for a professional additive manufacturing supplier and getting the newest quotations for our PREP atomizing system, or have any other questions, please click the button and leave us messages.

Neuester Blog

The preparation and research of Spherical Molybdenum Powder for 3D Printing prepared by Plasma Rotating Electrode Process

By Shanghai Truer Background Molybdenum has excellent properties such as high temperature strength, good electrical and thermal conductivity, good heat and fatigue resistance, and low toxicity. It is used in aerospace, nuclear industry, electronics industry, and medical fields. However, its

The Application of Molybdenum and its alloys on 3D printing

Adapted from B01, Issue 23, 2023 of World Metal Herald Background As is well known, due to its excellent high-temperature strength, molybdenum metal has become an indispensable raw material in many industries. In practical applications, sometimes complex shaped components are