As the main consumable for metal 3D printing, metal powder has a crucial impact on the quality of printed products. This article mainly compares two commonly used high-quality metal powder preparation processes, vacuum induction melting argon atomization (VIGA) and plasma rotating electrode method (PREP), and the performance of 3D printed metal powders produced by the two powders.

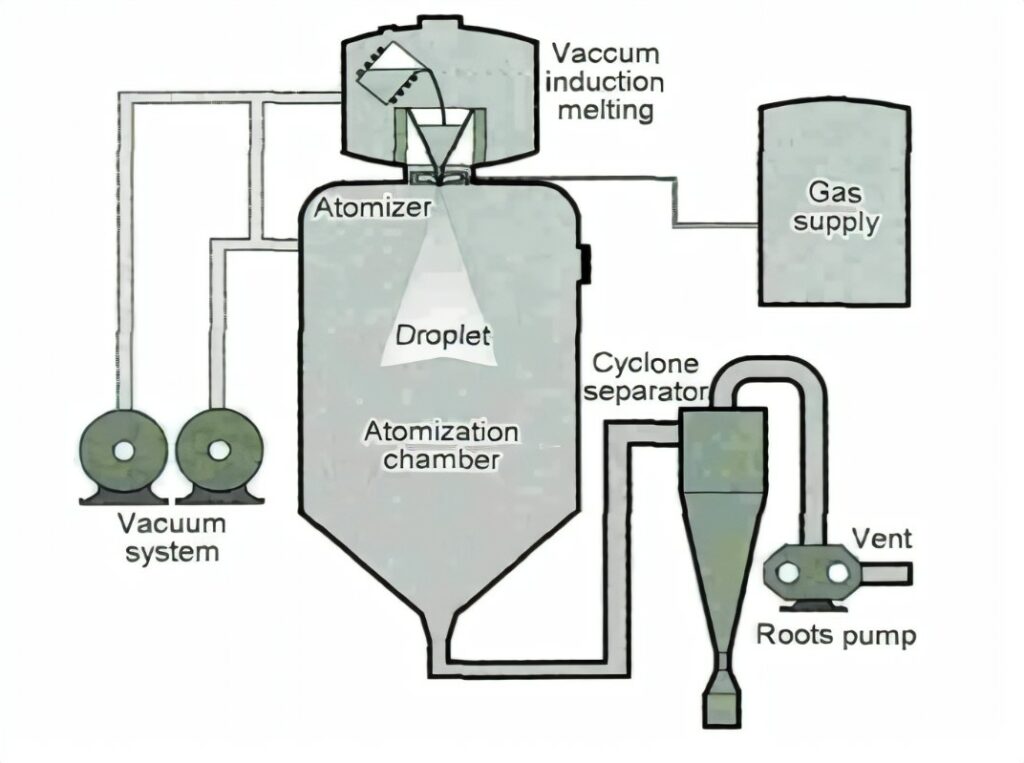

VIGA Metal Powder Making Method

AA method of powder making is a powder making method that uses a fast flowing argon gas stream to impact the metal liquid, break it into fine particles, and then condense it into a solid powder. In the conventional crucible argon atomization method powder (VIGA) method, the metal melt to contact the crucible, refractory erosion may be added to the metal powder ceramic inclusions, especially in the preparation of active metal powder (such as titanium alloy powder), the metal will react with the refractory, not only will increase inclusions, refractory elements will be reduced into the metal melt, so that the powder composition changes.

In order to improve the powder purity, the conventional argon atomization method was optimized and the crucible-free argon atomization (EIGA) method was proposed. The EIGA method melts the slowly rotating electrode material by a high-frequency induction coil and forms a fine liquid stream by controlling the melting parameters (the liquid stream does not need to touch the water-cooled crucible and guide tube), and when the alloy liquid stream flows through the atomization nozzle, the liquid stream is broken up and solidified by the high-speed pulsed airflow from the atomization nozzle to form fine powder particles. The disadvantage is that the particle size of the metal powder made by domestic technology is coarse and large, and the bias of the electrode will also lead to the non-uniform composition of the alloy powder material.

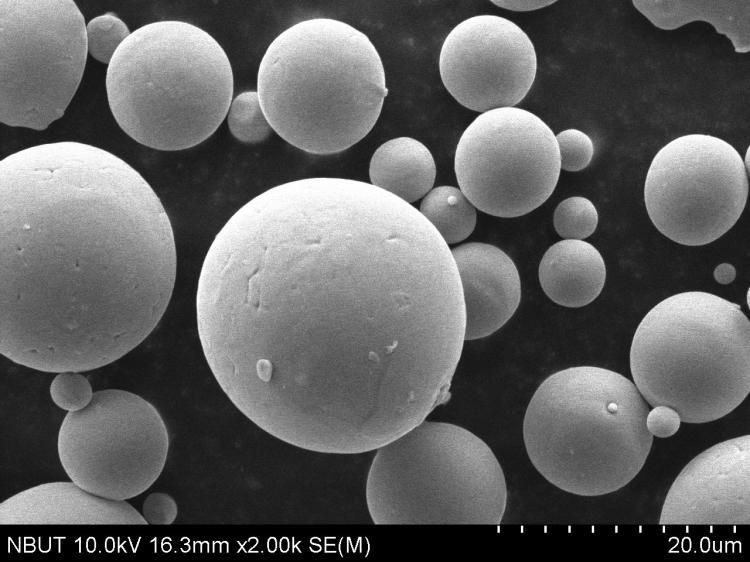

AA method has the advantages of low environmental pollution, high powder sphericity, controllable particle size and low oxygen content, and is the main preparation method for high performance and special alloy powders. However, the crushing efficiency of AA method for metal liquid is lower than that of water atomization, and there are hollow powder, flaky powder and satellite powder and other shaped powder, and the powder size distribution range is wide. In addition, the equipment is not easy to clean due to the large furnace body and complicated piping of AA method. Therefore, the preparation of different metal powders will cause cross-contamination due to incomplete furnace cleaning, which will reduce the purity and quality of the metal powder, which will seriously affect the performance of metal powder parts.

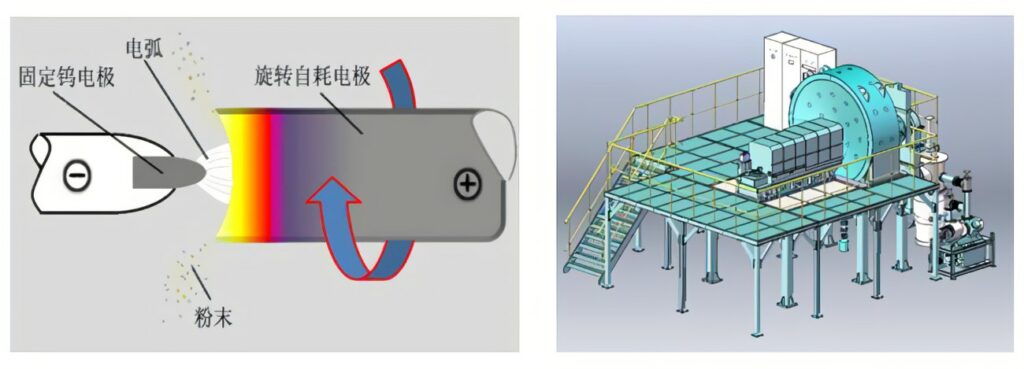

PREP Powder Making Method

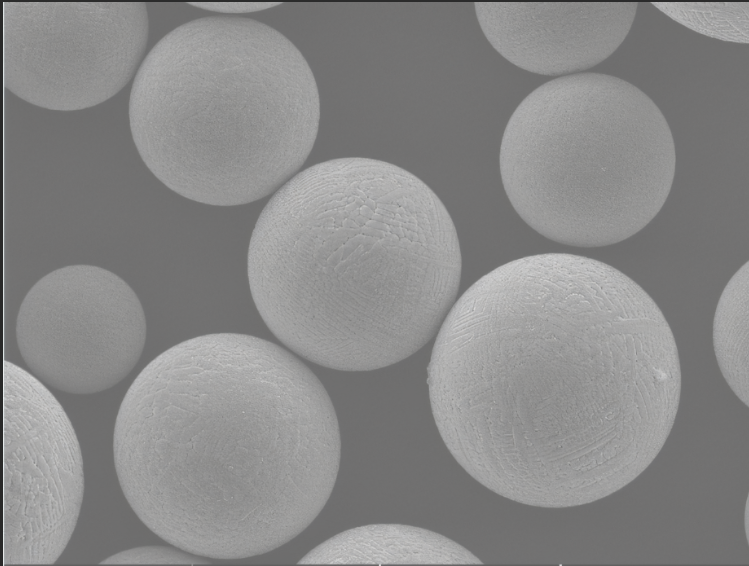

PREP method is to make the alloy of powder making into the electrode, using plasma arc to make it partially melted, the alloy electrode rotates in inert gas at high speed, and the melted metal forms spherical alloy powder under the action of centrifugal force, and the powder size can be controlled by adjusting the rotational speed and diameter of the electrode rod to improve the yield of specific size powder. The high-quality spherical metal powders prepared by this method are free from refractory contamination and therefore have minimal ceramic inclusions (mainly from the parent alloy) and higher cleanliness. In addition, the furnace body is easy to clean, so there is no cross-contamination due to poor cleaning after the preparation of different metal powders.

The furnace is easy to clean and does not cause cross-contamination due to poor cleaning after the preparation of different metal powders.

3D printing with PREP powder has the following advantages: (1) higher sphericity, surface finish, good fluidity, high bulk density, so good uniformity of powder laying, high density of printed products; (2) small powder particle size, narrow particle size distribution, low oxygen content, less/no spherification, agglomeration phenomenon, good melting effect, the high surface finish of products, and the consistency and uniformity of printing can be fully guaranteed; (3) basically there is no hollow powder, satellite powder, the printing process will not exist in the air gap, involvement and precipitation pores, cracks and other defects brought about by the hollow ball. The printed parts with AA powder have obvious porosity and low densities, while the densities of products printed with PREP powder are significantly improved.

The traditional PREP method has small diameter electrode rods, low speed, and cannot be produced continuously, and has problems such as coarse powder size and low efficiency. In order to meet the requirements of high-quality 3D printing metal powder, a new generation of plasma rotary electrode atomization powder technology and equipment (N-PREP) has been developed, which has a maximum electrode diameter of 70-100 mm, a limit speed of 18,000-30,000 r/min, and an integrated continuous bar feeding technology, with a bar loading capacity of more than 50 bars/time and a prepared powder particle size of d50 not The maximum diameter of the electrode reaches 70~30,000 mm, and the maximum speed reaches 18,000~30,000 r/min.

Other Metal Powder Preparation Technologies for 3D Printing

In addition to the above-mentioned powder-making technologies, coaxial jet water-air combined atomization method, plasma spheroidization processing technology is also used to prepare 3D printing metal powder. Coaxial jet water-gas combined atomization powder making technology uses high-pressure gas to pre-crush the melt, which is pulled and drawn, broken into small droplets, and then high-pressure water impinges on the large droplets to break them into even finer droplets. This technology combines the low cost of water atomization while maintaining the advantages of high sphericity and low oxygen content of aerosolization, and the prepared powder has better sphericity than water atomization, finer powder size than aerosolization, and lower oxygen content than water atomization. Plasma spheroidization technology is through the carrier gas to send the powder into the high-temperature plasma, the powder particles quickly absorb heat after the surface (or the whole) melt, under the action of surface tension condensation into spherical droplets, into the cooling chamber after the sudden cold solidification and will be spherical fixed down, so as to obtain a dense spherical powder.

Powder Performance Comparison

VIGA powder is basically spherical in shape, containing satellite bonded powder, encapsulated powder, broken powder, hollow powder, and irregular powder. The average particle size is fine, and the size distribution range is wide, with 16.5% (mass fraction) of the powder less than 50 μm and 46.6% (mass fraction) of the powder yield from 50 to 150 μm. The powder has a high content of ceramic inclusions, mainly from the parent alloy and the refractory material of the atomization process. The powder productivity is relatively high.

PREP powder is mostly spherical, irregular powder and hollow powder is less, the surface is smooth and clean. The powder size is large, the size distribution range is narrow, the powder less than 50 μm has 0.4% (mass fraction), 50 ~ 150 μm powder yield is 85.3% (mass fraction).

Number. The purity is high, basically maintaining the level of the alloy bar, without crucible contamination. The production efficiency is relatively low.

PREP method in the preparation of ultra-fine spherical powder (particle size not larger than 50 μm), the yield is not high and the production efficiency is relative which is less used in powder spreading type 3D printing equipment. Therefore, there is an urgent need to optimize the process and develop a new generation of plasma rotating electrode atomized powder technology and equipment to further improve the yield of ultrafine spherical metal powder yield, and realize the common nickel-based, cobalt-based alloy and titanium alloy The technology and equipment are developed to further improve the yield of ultra-fine spherical metal powders and to realize the continuous production of high quality ultra-fine spherical metal powders such as nickel-based, cobalt-based alloys and titanium alloys in large quantities, thereby The cost performance of PREP method metal powder can be improved and adapted to various The PREP method can be applied to a wide range of 3D printing devices and be more widely used in the field of 3D printing.

3 Comments

Good comparison between VIGA and PREP for metal powder production.

Your posts in this blog really shine! Glad to gain some new insights, which I happen to also cover on my page. Feel free to visit my webpage Webemail24 about Senior Health and any tip from you will be much apreciated.

Very good article! We will bee linking to this great article onn our site.

Keep up the good writing. https://odessaforum.Biz.ua/