This article focuses on the properties and applications of powdered metal materials commonly used in aerospace, high strength stainless steel powders prepared using PREP( Plasma rotating electrode process).

Background to the Application of the PREP

The use of additive manufacturing in aerospace, biomedical and automotive applications has resulted in the widespread use of high-strength stainless steel, titanium aluminum, titanium alloys, nickel-based alloys and high-temperature alloys due to their excellent material properties.

The requirements of SEBM technology in terms of powder flow, bulk density, impurity content, and sphericity have led to an increasing interest in the preparation of powders by PREP equipment.

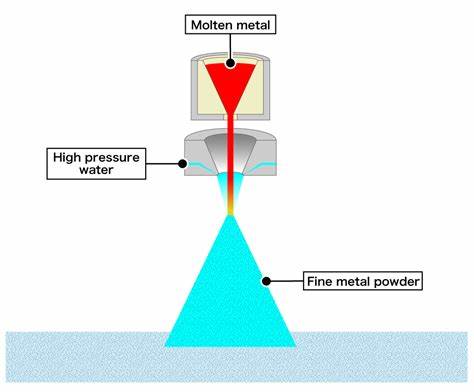

The main methods used to prepare metal powders are Water atomization, WA, Gas atomization, GA, and Plasma atomization, GA. Plasma atomization, PA, Plasma rotating electrode process, PREP. Hydride-dehydride, HDH, etc. Compared with other preparation methods, the PREP powder has the advantages of good sphericity, smooth powder surface, less satellite powder, and hollow powder, high purity, good flowability, and narrow particle size distribution, meeting the basic requirements of SEBM technology for raw materials.

water atomization

High-strength Stainless Steel Metal Powder Materials for Aerospace Applications

According to statistics, the amount of steel used in aircraft structural materials is approximately 5% to 10%. High-strength stainless steel is usually used in structural parts that require materials with high specific strength, high stiffness, high fatigue life and good medium temperature strength, corrosion resistance and other characteristics.

Low-temperature technology and equipment is a new direction of development of high strength stainless steel, such as, for example, equipped with hydrogen fuel aircraft. Therefore, suitable for use in low-temperature conditions of martensitic aging stainless steel is the most promising use of high strength stainless steel.

High-strength stainless steel powder such as the commonly used 316L, because 316L stainless steel added Mo, so its corrosion resistance, atmospheric corrosion resistance, and high-temperature strength are particularly good, and can be used in harsh conditions. 316L stainless steel belongs to the austenitic stainless steel, and can not be strengthened by heat treatment. It has good strength, plasticity, toughness and cold formability, and good low-temperature properties.

316L powder

Properties of High–strength Stainless Steel Powders Made by PREP

As the powder size decreases from 180 μm to 45 μm, the flow of the powder becomes better, and as the size continues to decrease, the flow becomes slightly worse. This is because as the powder size decreases within a certain size range, the sphericity of the powder becomes better and the surface of the powder becomes smoother, resulting in better flow, however, when the size is too small, the powder tends to adhere to the inner wall of the funnel, resulting in a poor flow.

This is because the specific surface area of the powder increases as the particle size decreases and the friction between the powders increases, while the porosity of the powder increases due to the electrostatic effect between the powders, resulting in a decrease in bulk and compaction density.

In addition, the oxygen content of the high-strength stainless steel powder prepared by the PREP method is lower, compared to the bar, because the PREP powder making process, the atomisation chamber is in a vacuum pollution-free state, so the powder is less likely to be oxidized, the oxygen increment is smaller, but the reduction in particle size makes the oxygen content of the powder increase, this is due to the finer the particle size, the powder’s specific surface area increases.

The above is a brief analysis of some of the physical properties of high-strength stainless steel powders made with PREP.

For more information on high-strength stainless steel powders and PREP equipment please feel free to contact us.